Manual Cylinder Filter Press

✧ Product Features

A、Filtration pressure<0.5Mpa

B、Filtration temperature:45℃/ room temperature; 80℃/ high temperature; 100℃/ High temperature. The raw material ratio of different temperature production filter plates is not the same, and the thickness of filter plates is not the same.

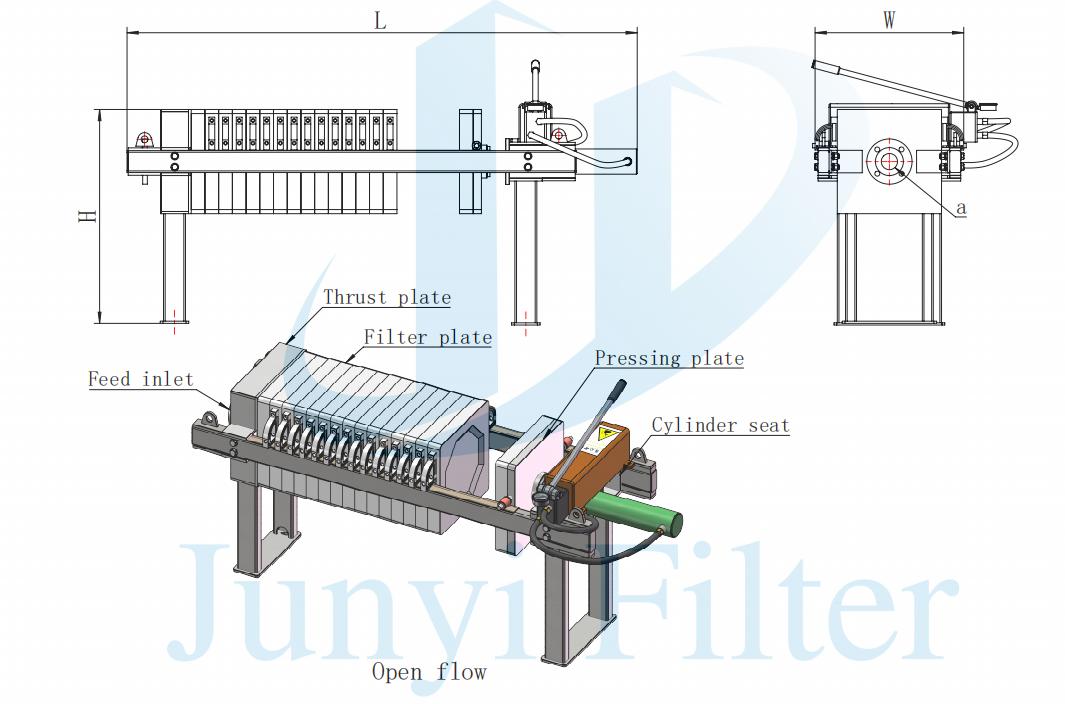

C-1、Discharge method - open flow: Faucets need to be installed below the left and right sides of each filter plate, and a matching sink. Open flow is used for liquids that are not recovered.

C-2、Liquid discharge method close flow:Under the feed end of the filter press, there are two close flow outlet main pipes, which are connected with the liquid recovery tank. If the liquid needs to be recovered, or if the liquid is volatile, smelly, flammable and explosive, dark flow is used.

D-1、Selection of filter cloth material: The pH of the liquid determines the material of the filter cloth. PH1-5 is acidic polyester filter cloth, PH8-14 is alkaline polypropylene filter cloth. The viscous liquid or solid is preferred to choose twill filter cloth, and the non-viscous liquid or solid is selected plain filter cloth.

D-2、Selection of filter cloth mesh: The fluid is separated, and the corresponding mesh number is selected for different solid particle sizes. Filter cloth mesh range 100-1000 mesh. Micron to mesh conversion (1UM = 15,000 mesh---in theory).

E、Rack surface treatment: PH value neutral or weak acid base; The surface of the filter press frame is sandblasted first, and then sprayed with primer and anti-corrosion paint. The PH value is strong acid or strong alkaline, the surface of the filter press frame is sandblasted, sprayed with primer, and the surface is wrapped with stainless steel or PP plate.

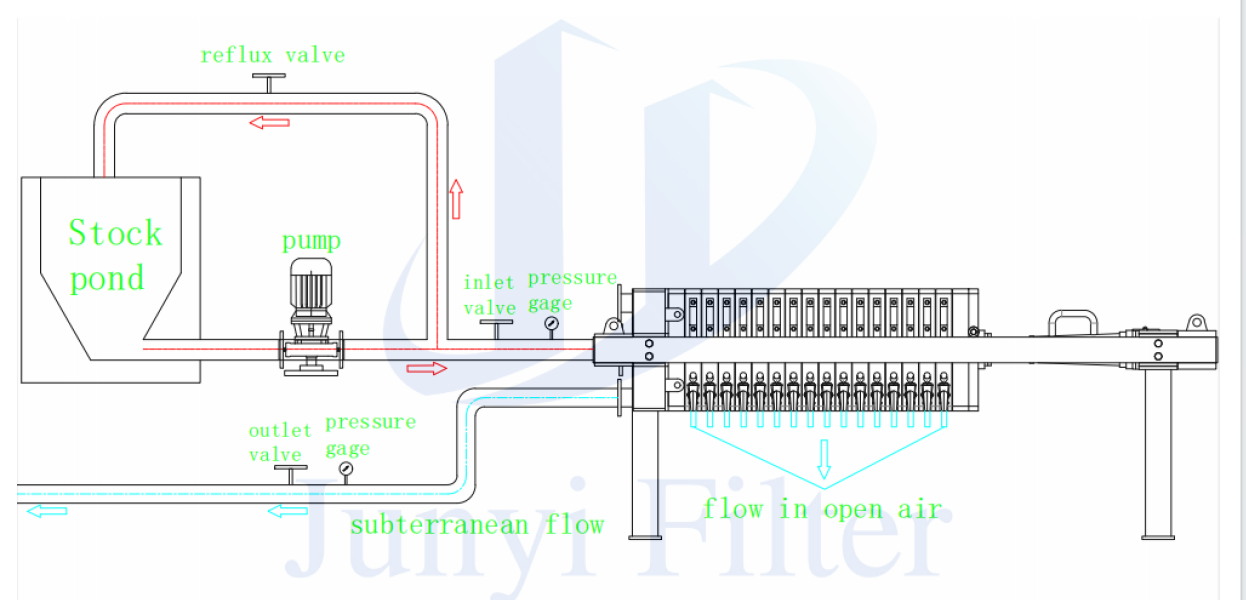

✧ Feeding Process

✧ Application Industries

Petroleum, chemical, pharmaceutical, sugar, food, coal washing, oil, printing and dyeing, brewing, ceramics, mining metallurgy, sewage treatment and other fields.

✧ Filter Press Ordering Instructions

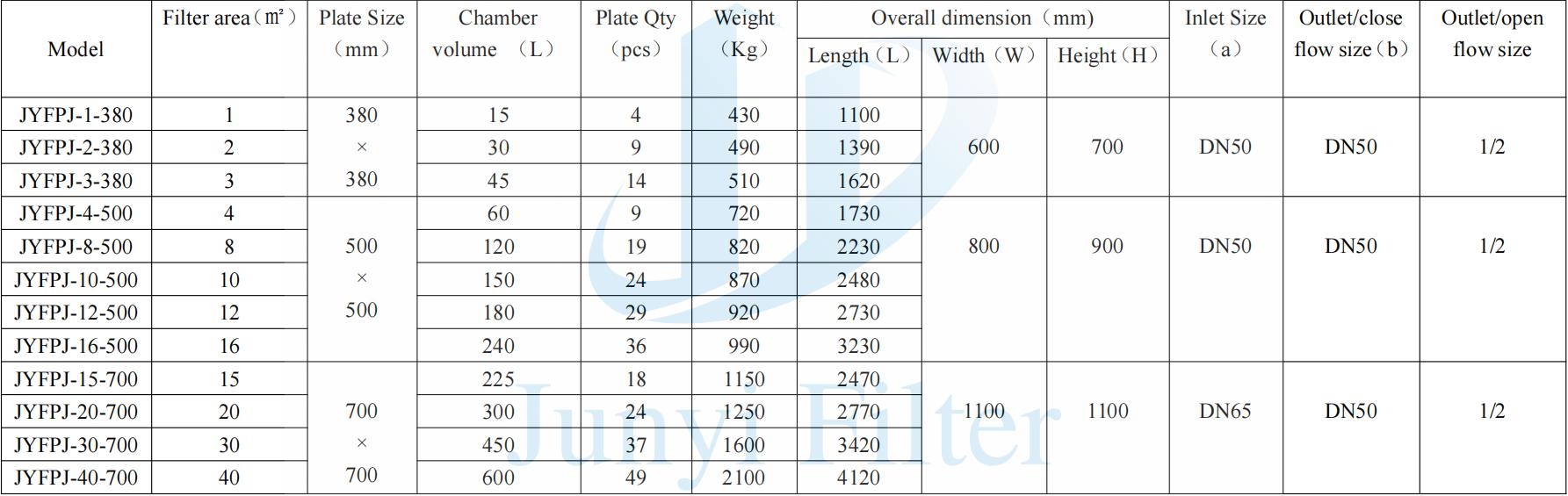

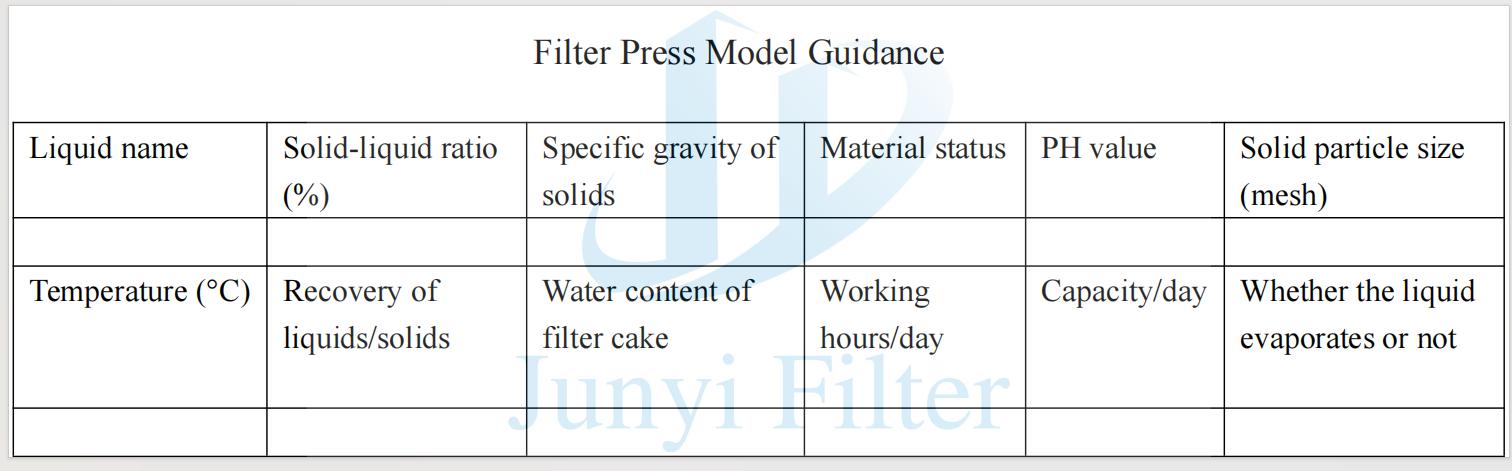

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.