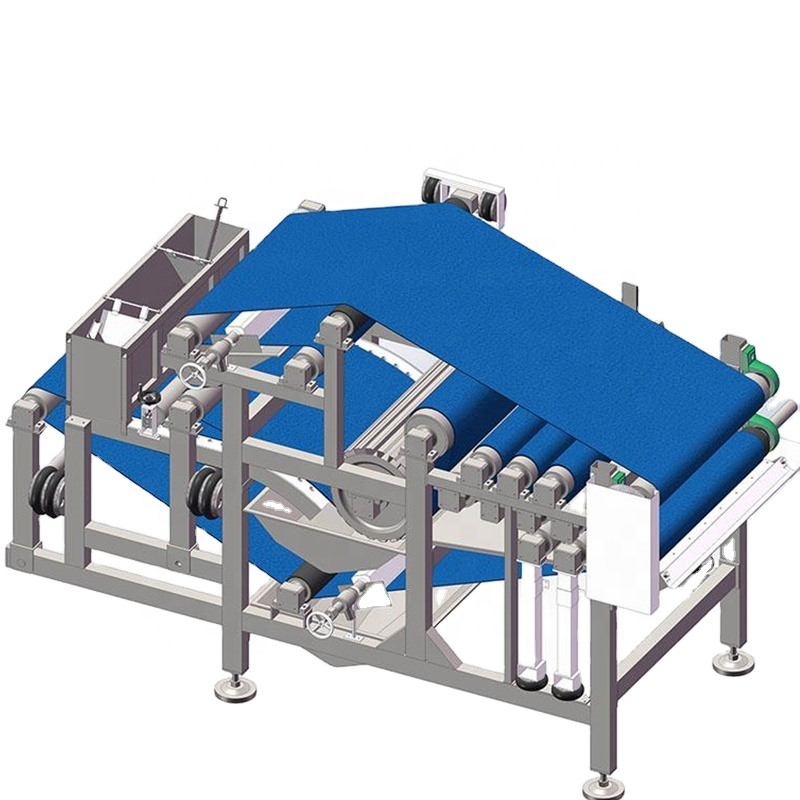

Stainless Steel Filter Plate

✧ Product Features

The stainless steel filter plate is made of 304 or 316L all stainless steel, with a long service life, corrosion resistance, good acid and alkaline resistance, and can be used for filtering food grade materials.

1. The stainless steel filter plate is welded to the outer edge of the stainless steel wire mesh as a whole. When the filter plate is backwashed, the wire mesh is firmly welded to the edge. The outer edge of the filter plate will not tear or cause damage, ensuring the quality of the filtered liquid without the need for frequent replacement.

2. The stainless steel filter plate and stainless steel wire mesh have high strength and are not affected by the flushing strength.

3. Stainless steel wire mesh is not easy to adhere impurities and block. After filtering the liquid, it is easier to rinse and is more suitable for filtering high viscosity and high strength liquids.

✧ Parameter list

| Model(mm) | PP Camber | Diaphragm | Closed | Stainless steel | Cast Iron | PP Frame and Plate | Circle |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ | √ | √ | √ | ||

| 630×630 | √ | √ | √ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ | √ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ | √ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Temperature | 0-100℃ | 0-100℃ | 0-100℃ | 0-200℃ | 0-200℃ | 0-80℃ | 0-100℃ |

| Pressure | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |

| Filter Plate Parameter List | |||||||

| Model(mm) | PP Camber | Diaphragm | Closed | Stainless steel | Cast Iron | PP Frame and Plate | Circle |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ |

√ | √ | √ | ||

| 630×630 | √ | √ |

√ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ |

√ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ |

√ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Temperature | 0-100℃ | 0-100℃ | 0-100℃ | 0-200℃ | 0-200℃ | 0-80℃ | 0-100℃ |

| Pressure | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |