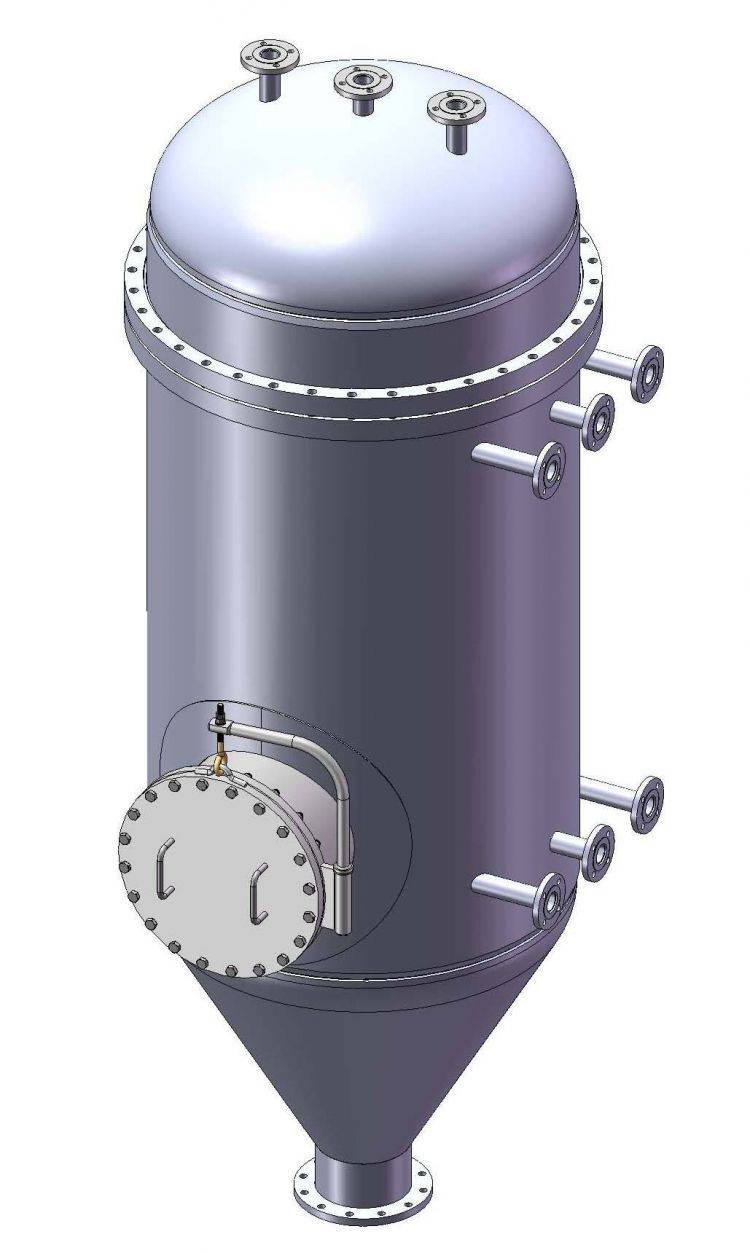

Stainless Steel Automatic Microporous Filter For Fine Filtration Of Syrups For Food Production

✧ Product Features

1. This machine is small in size, light in weight, easy to use, large in filtration area, low in clogging rate, fast in filtration speed, no pollution, good in thermal dilution stability and chemical stability.

2. This filter can filter out most of the particles, so it is widely used in fine filtration and sterilization process.

3. Material: 304 316L can be lined with anti-corrosive materials, rubber, PTFE.

4. Folded cartridge lengths are 10, 20, 30, 40 inches.

5. Filter material polytetraethylene, polysulfone, nylon, polypropylene, acetate fiber.

6.Filter pore size: 0.1um, 0.22um, 1um, 3um, 5um, 10um, etc.

7. The cartridge can be equipped with 1 core, 3 cores, 5 cores, 7 cores, 9 cores, 11 cores, 13 cores, 15 cores and so on.

8 Hydrophobic (for gas) and hydrophilic (for days of liquid) cartridges, the user must be in accordance with the use of filtration, media, configuration of different forms of different materials of the cartridge before use.

✧ Application Industries

powdered activated carbon for pharmaceutical and food production;

Filtration of herbal medicine juice

Oral medicinal liquids, injection medicinal liquids, tonic liquids, medicinal wines, etc.

Syrup for pharmaceutical and food production

Fruit juice, soy sauce, vinegar, etc;

Iron sludge filtration for pharmaceutical and chemical production

Filtration of catalyst and other ultra-fine particles in pharmaceutical and fine chemical production.

Working Principle:

Liquid flows into the filter from the inlet under a certain pressure, impurities are retained by the filter media inside the filter, and the filtered liquid flows out from the outlet. When filtering to a certain stage, the pressure difference between the import and export increases, and the cartridge needs to be backwashed, at which time the backwash valve is opened, and the hydraulic pressure flows from the backwash inlet to the rinse from bottom to top, and the filter resumes its filtering function.

The filter element is a replaceable element, when the filter runs for a certain period of time, the filter element will be removed and replaced with a new one to ensure the precision and efficiency of filtration.

✧Maintenance and care of microporous filters:

Microporous filter is now widely used in medicine, chemical industry, electronics, beverage, fruit wine, biochemical water treatment, environmental protection and other essential equipment for industry. Therefore, its maintenance is very necessary, not only to enhance the filtration precision, but also to extend the service life of the microporous filter. What do we have to do to do a good job on the maintenance of the microporous filter? The maintenance of microporous filter is divided into two types of microporous filters, namely, precision microporous filter and coarse filter microporous filter.1, precision microporous filter ①, the core part of the precision microporous filter is the filter cartridge, the filter cartridge is composed of special materials, which is a wear-and-tear part, and needs special protection. ②, when the precision microporous filter works for a period of time, the filter cartridge intercepts a certain amount of impurities, when the pressure drop increases, the flow rate will decrease, the impurities in the filter need to be removed in time, and at the same time, the filter cartridge should be cleaned. ③, when removing impurities, pay special attention to the precision cartridge, shall not be deformed or damaged, otherwise, the cartridge will be installed again, and the purity of the filtered medium will not meet the design requirements. Certain precision cartridges cannot be used repeatedly for many times, such as bag cartridge and polypropylene cartridge. ⑤, if the filter element is found to be deformed or damaged, it needs to be replaced immediately.2 Coarse Filter Microporous Filter ①, the core part of the coarse filter microporous filter is the filter core, which consists of the filter frame and stainless steel wire mesh, and the stainless steel wire mesh is a wear-and-tear part, which needs to be specially protected. ②, when the filter works for a period of time, a certain amount of impurities precipitated in the filter core, when the pressure drop increases, the flow rate will decrease, and the impurities in the filter core need to be removed in time. ③, when cleaning impurities, pay special attention to the stainless steel wire mesh on the filter core can not be deformed or damaged, otherwise, the filter will be mounted on the filter, the purity of the filtered medium will not meet the design requirements, and the compressor, pumps, instruments and other equipment will be damaged. If the stainless steel wire mesh is found to be deformed or damaged, it needs to be replaced immediately.