Small Manual Water Treatment Anticorrosive Filter Press Equipment For Soft Drinks

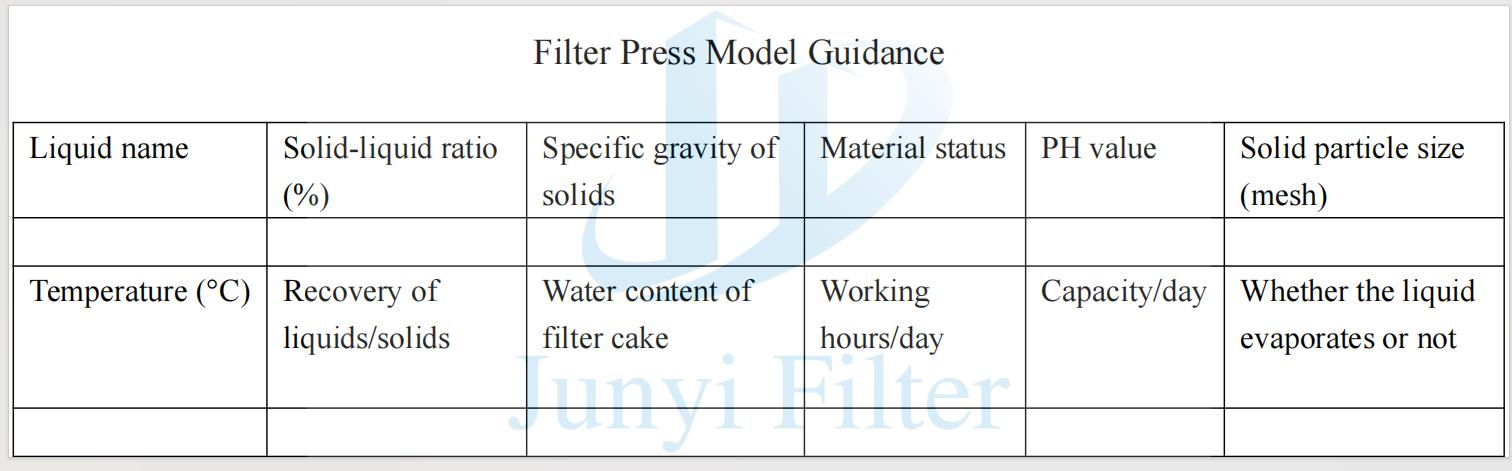

a. Filtration pressure<0.5Mpa

b. Filtration temperature: 45℃/ room temperature; 80℃/ high temperature; 100℃/ High temperature. The raw material ratio of different temperature production filter plates is not the same, and the thickness of filter plates is not the same.

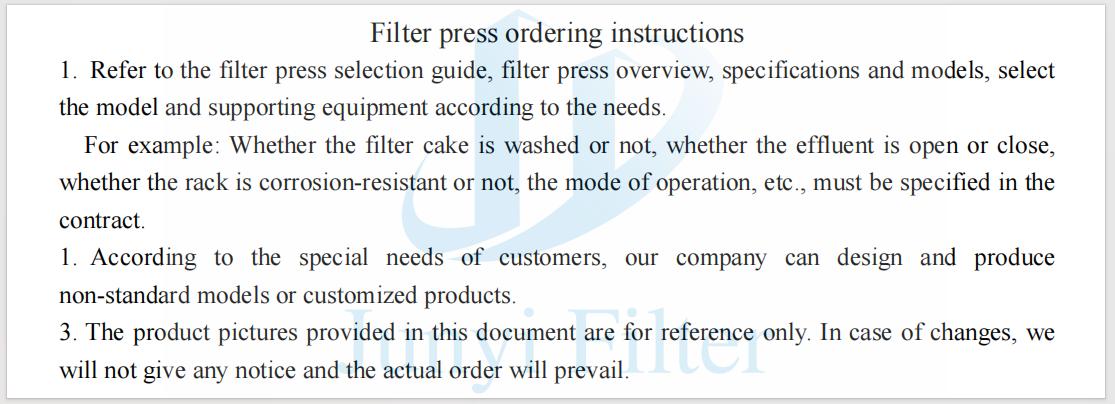

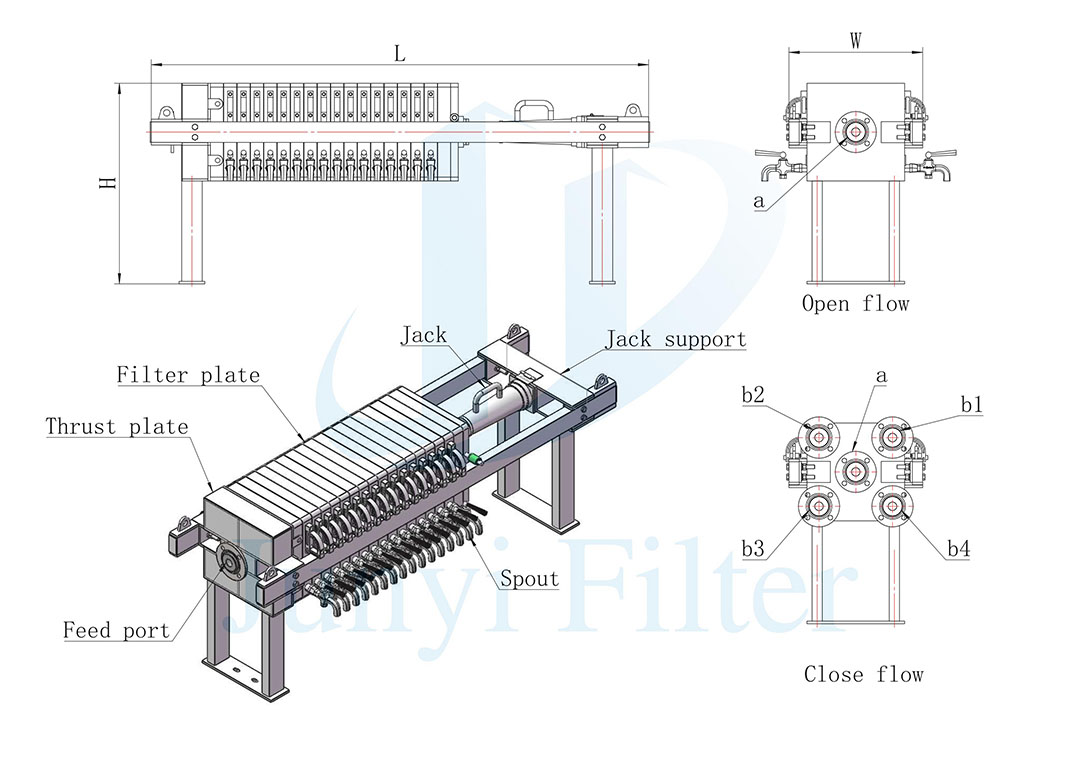

c-1. Discharge method - open flow: Faucets need to be installed below the left and right sides of each filter plate, and a matching sink. Open flow is used for liquids that are not recovered.

c-2. Liquid discharge method close flow: Under the feed end of the filter press, there are two close flow outlet main pipes, which are connected with the liquid recovery tank. If the liquid needs to be recovered, or if the liquid is volatile, smelly, flammable and explosive, dark flow is used.

d-1. Selection of filter cloth material: The pH of the liquid determines the material of the filter cloth. PH1-5 is acidic polyester filter cloth, PH8-14 is alkaline polypropylene filter cloth. The viscous liquid or solid is preferred to choose twill filter cloth, and the non-viscous liquid or solid is selected plain filter cloth.

d-2. Selection of filter cloth mesh: The fluid is separated, and the corresponding mesh number is selected for different solid particle sizes. Filter cloth mesh range 100-1000 mesh. Micron to mesh conversion (1UM = 15,000 mesh---in theory).

e. Rack surface treatment: PH value neutral or weak acid base; The surface of the filter press frame is sandblasted first, and then sprayed with primer and anti-corrosion paint. The PH value is strong acid or strong alkaline, the surface of the filter press frame is sandblasted, sprayed with primer, and the surface is wrapped with stainless steel or PP plate.

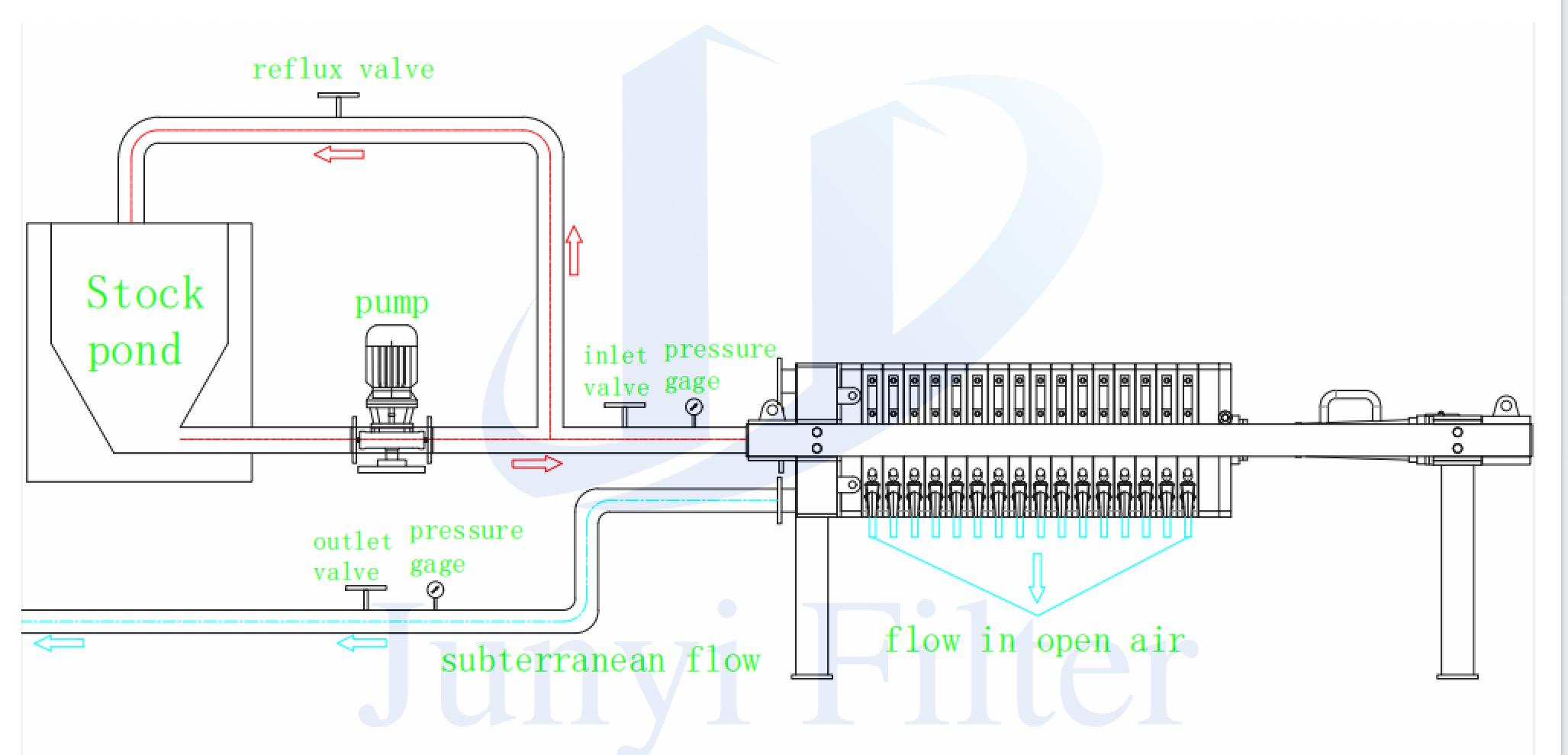

Feeding process

Application Industries

Petroleum, chemical, pharmaceutical, sugar, food, coal washing, oil, printing and dyeing, brewing, ceramics, mining metallurgy, sewage treatment and other fields.

Filter press operation specification1. According to the process requirements to make pipeline connection, and do water inlet test, detect the air tightness of the pipeline;

2. For the connection of the input power supply (3 phase + neutral), it is best to use a ground wire for the electric control cabinet;

3. Connection between control cabinet and surrounding equipment. Some wires has been connected. The output line terminals of the control cabinet are labeled. Refer to the circuit diagram to check the wiring and connect it. If there is any looseness in the fixed terminal, compress again;

4. Fill the hydraulic station with 46 # hydraulic oil, the hydraulic oil should be seen in the tank observation window. If the filter press operates continuously for 240 hours, replace or filter the hydraulic oil;

5. Installation of cylinder pressure gauge. Use a wrench to avoid manual rotation during installation. Use an O-ring at the connection between the pressure gauge and the oil cylinder;

6. The first time the oil cylinder runs, the motor of the hydraulic station should be rotated clockwise (indicated on the motor). When the oil cylinder is pushed forward, the pressure gauge base should discharge air, and the oil cylinder should be repeatedly pushed forward and backward (the upper limit pressure of the pressure gauge is 10Mpa) and air should be discharged simultaneously;

7. The filter press runs for the first time, select the manual state of control cabinet to run different functions respectively; After the functions are normal, you can select the automatic state;

8. Installation of filter cloth. During the trial operation of the filter press, the filter plate should be equipped with filter cloth in advance. Install the filter cloth on the filter plate to ensure that the filter cloth is flat and there are no creases or overlaps. Manually push the filter plate to ensure that the filter cloth is flat.

9. During the operation of the filter press, if an accident occurs, the operator presses the emergency stop button or pulls the emergency rope;