Products

-

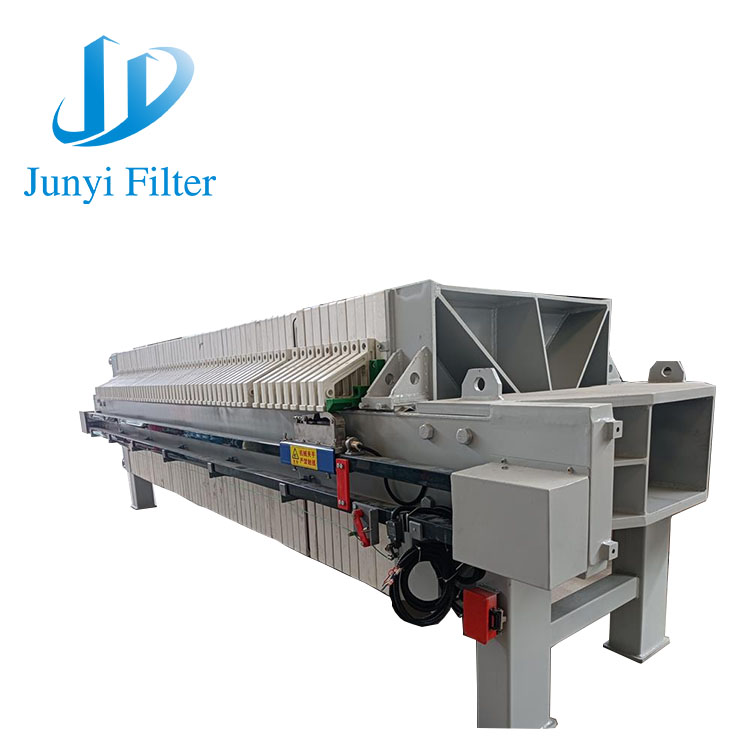

Chamber-type automatic hydraulic compression automatic pulling plate automatic pressure keeping filter presses

Programmed automatic pulling plate chamber filter presses is not manual operation, but a key start or remote control and achieve full automation. Junyi’s chamber filter presses are equipped with an intelligent control system with an LCD display of the operating process and a fault warning function. At the same time, the equipment adopts Siemens PLC automatic control and Schneider components to ensure the overall operation of the equipment. In addition, the equipment is equipped with safety devices to ensure safe operation.

Programmed automatic pulling plate chamber filter presses is not manual operation, but a key start or remote control and achieve full automation. Junyi’s chamber filter presses are equipped with an intelligent control system with an LCD display of the operating process and a fault warning function. At the same time, the equipment adopts Siemens PLC automatic control and Schneider components to ensure the overall operation of the equipment. In addition, the equipment is equipped with safety devices to ensure safe operation. -

Automatic pull plate double oil cylinder large filter press

Automatic hydraulic filter press is a batch of pressure filtration equipment, mainly used for solid-liquid separation of various suspensions. It has the advantages of good separation effect and convenient use, and is widely used in petroleum, chemical industry, dyestuff, metallurgy, pharmacy, food, paper making, coal washing and sewage treatment . Automatic hydraulic filter press is mainly composed of the following parts: rack part : includes a thrust plate and a compression plate to support the whole filter mechanism . filter part : composed of filter plate and filter cloth to form a filter unit to realize solid-liquid separation . hydraulic part : hydraulic station and cylinder composition, provide power, to complete the pressing and release action . electrical part : control the operation of the whole filter press, including starting, stopping and the adjustment of various parameters . The working principle of the automatic hydraulic filter press is as follows: When working, the piston in the cylinder body pushes the pressing plate, the filter plate and the filter medium are pressed, so that the material with working pressure is pressurized and filtered in the filter chamber. The filtrate is discharged through the filter cloth, and the cake remains in the filter chamber. After completion, the hydraulic system is automatically released, the filter cake is released from the filter cloth by its own weight, and the unloading is completed . Advantages of fully automatic hydraulic filter press include: efficient filtration : reasonable flow channel design, short filtration cycle, high work efficiency . strong stability : hydraulic system safe and reliable, easy operation and maintenance . widely applicable : suitable for the separation of a variety of suspension, stable and reliable performance . easy operation : high degree of automation, reduce manual operation, improve production efficiency .

-

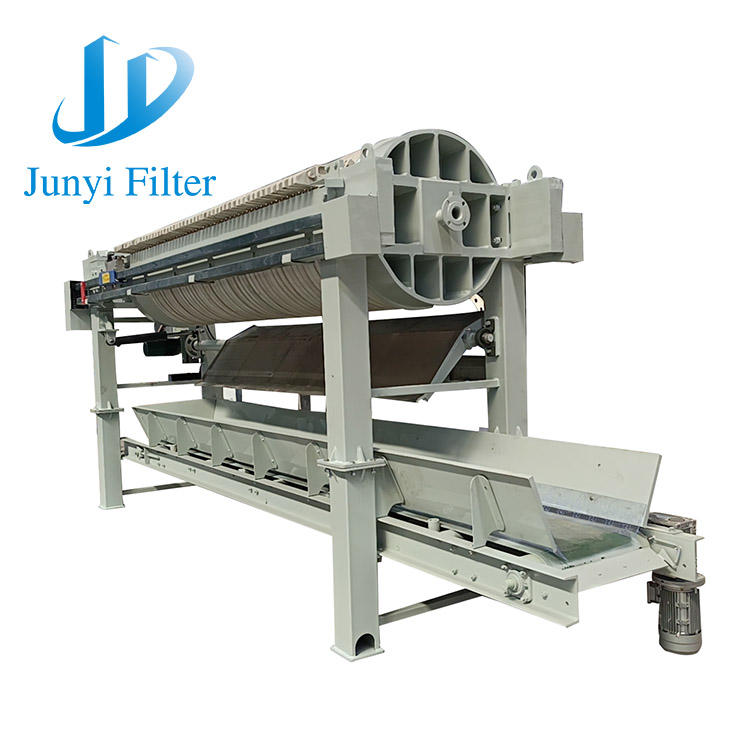

High efficiency and energy saving circulating circular filter press with low water content in filter cake

Junyi round filter press is made of round filter plate and high pressure resistant frame. It has the advantages of high filtration pressure, high filtration speed, low water content of filter cake, etc. The filtration pressure can be as high as 2.0MPa. The round filter press can be equipped with conveyor belt, mud storage hopper and mud cake crusher,

Junyi round filter press is made of round filter plate and high pressure resistant frame. It has the advantages of high filtration pressure, high filtration speed, low water content of filter cake, etc. The filtration pressure can be as high as 2.0MPa. The round filter press can be equipped with conveyor belt, mud storage hopper and mud cake crusher, -

Industrial-grade self-cleaning filters with advanced technology for the food industry

The cleaning component is a rotating shaft which there are suction nozzles on it instead of brush/scraper.

The self-cleaning process is completed by the sucking scanner and the blow-down valve, which move spirally along the inner surface of the filter screen. The opening of the blow-down valve generates a high backwash flow rate at the front end of the suction nozzle of the sucking scanner and forms a vacuum. The solid particles attached to the inner wall of the filter screen is sucked out and discharged outside the body.

During the whole cleaning process, the system does not stop the flow, realize the continuous working. -

Industrial-grade high-efficiency automatic self-cleaning filter with long life

The cleaning component is a rotating shaft which there are suction nozzles on it instead of brush/scraper.

The self-cleaning process is completed by the sucking scanner and the blow-down valve, which move spirally along the inner surface of the filter screen. The opening of the blow-down valve generates a high backwash flow rate at the front end of the suction nozzle of the sucking scanner and forms a vacuum. The solid particles attached to the inner wall of the filter screen is sucked out and discharged outside the body.

During the whole cleaning process, the system does not stop the flow, realize the continuous working. -

Stainless steel basket filter for sewage treatment

Mainly used on pipes for filtering oil or other liquids, thus filtering impurities from the pipes (in a confined environment). The area of its filter holes is 2-3 times larger than the area of the through-bore pipe. In addition, it has a different filter structure than other filters, shaped like a basket.

-

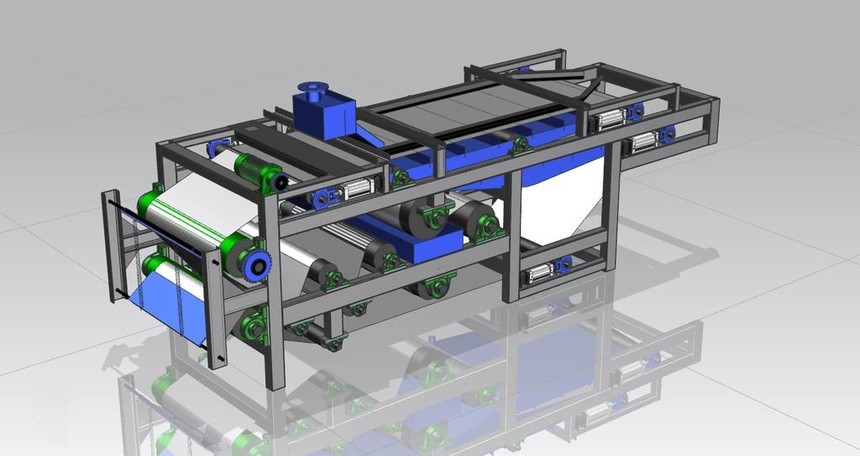

New function Fully automated belt filter press suitable for mining, sludge treatment

Integrated sewage treatment equipment

The sludge dewatering machine (sludge filter press) is equipped with a vertical thickening and pre-dehydration unit, which enables the dewatering machine to flexibly handle different types of sludge. The thickening section and the filter press section use vertical drive units, and different types of filter belts are used respectively. The overall frame of the equipment is made of stainless steel, and the bearings are made of polymer wear-resistant and corrosion-resistant materials, making the dewatering machine more durable and reliable, and requiring less maintenance. -

Stainless steel rack concealed flow stainless steel plate chamber filter press for food processing

Programmed automatic pulling plate chamber filter presses is not manual operation, but a key start or remote control and achieve full automation. Junyi’s chamber filter presses are equipped with an intelligent control system with an LCD display of the operating process and a fault warning function. At the same time, the equipment adopts Siemens PLC automatic control and Schneider components to ensure the overall operation of the equipment. In addition, the equipment is equipped with safety devices to ensure safe operation.

-

Industrial use of stainless steel diaphragm filter press for water treatment

Diaphragm press filter press is composed of diaphragm plate and chamber filter plate arranged to form a filter chamber, after the cake is formed inside the filter chamber, air or pure water is injected into the diaphragm filter plate, and the diaphragm’s diaphragm expands to fully press the cake inside the filter chamber to reduce the water content. Especially for the filtration of viscous materials and users who require high water content, this machine has its unique characteristics. The filter plate is made of reinforced polypropylene moulding, and the diaphragm and polypropylene plate are inlaid together, which is strong and reliable, not easy to fall off, and has a long service life.

-

Suitable for mining filter equipment vacuum belt filter large capacity

Product Introduction:

The vacuum belt filter is a relatively simple but efficient and continuous solid-liquidseparation device that uses a new technology. lt has better function in sludge dewateringand filtration process. And because of the special material of the filter belt, the sludge caneasily drop from the belt filter press. According to the different materials, the belt filter canbe configured with different specifications of filter belts to achieve higher filtrationaccuracy. As a professional belt filter press manufacturer, Shanghai Junyi Filter EquipmentCo., Ltd. will provide customers with the most suitable solution and the most favorableprice of belt filter press according to customers’ materials. -

Automatic brush type self-cleaning filter 50μm water treatment solid-liquid separation

Self-cleaning filter is a kind of use of filter screen to directly intercept impurities in the water, remove suspended solids and particles in the water body, reduce turbidity, purify water quality, reduce system dirt, algae, rust, etc., in order to purify water quality and protect the normal operation of other equipment of the system Precision equipment, water enters the self-cleaning filter body from the water inlet, due to the intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity deposition, and signal the sewage valve to automatically discharge the full blowdown.

-

Automatic Self-Cleaning Water filter for Industrial water purification

Self Cleaning FilterJunyi series self-cleaning filter is designed for continuous filtration to remove impurities, uses a high-strength filter mesh and stainless steel cleaning components, to filter, clean and discharge automatically.In the whole process, the filtrate does not stop flowing, realizing continuous and automatic production.Working Principle of Self-cleaning Filter

The liquid to be filtered flows into the filter through the inlet, then flows form inside to outside of the filter mesh, the impurities are intercepted on the inner of the mesh.When the pressure difference between inlet and outlet of the filter reaches the set value or the timer reaches the set time, the differential pressure controller sends a signal to motor to rotate the brush/scraper for cleaning, and the drain valve opens at the same time. The impurity particles on the filter mesh are brushed by the rotating brush/scraper, then discharged from the drain outlet.