PP Chamber Filter Plate

✧ Description

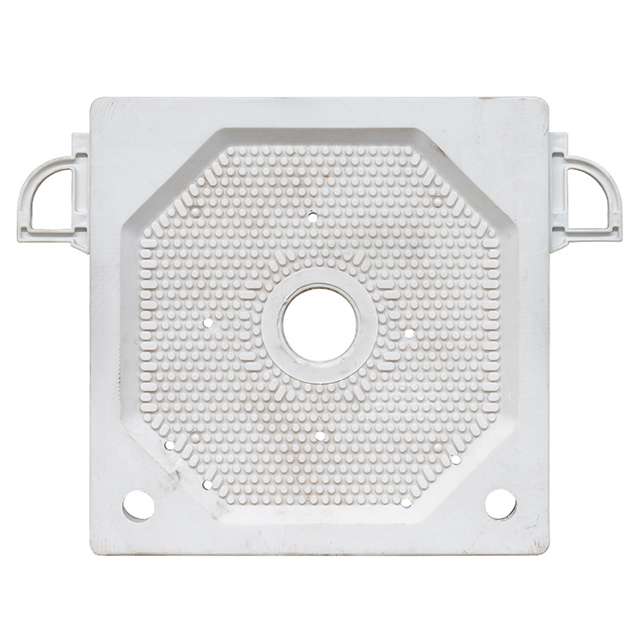

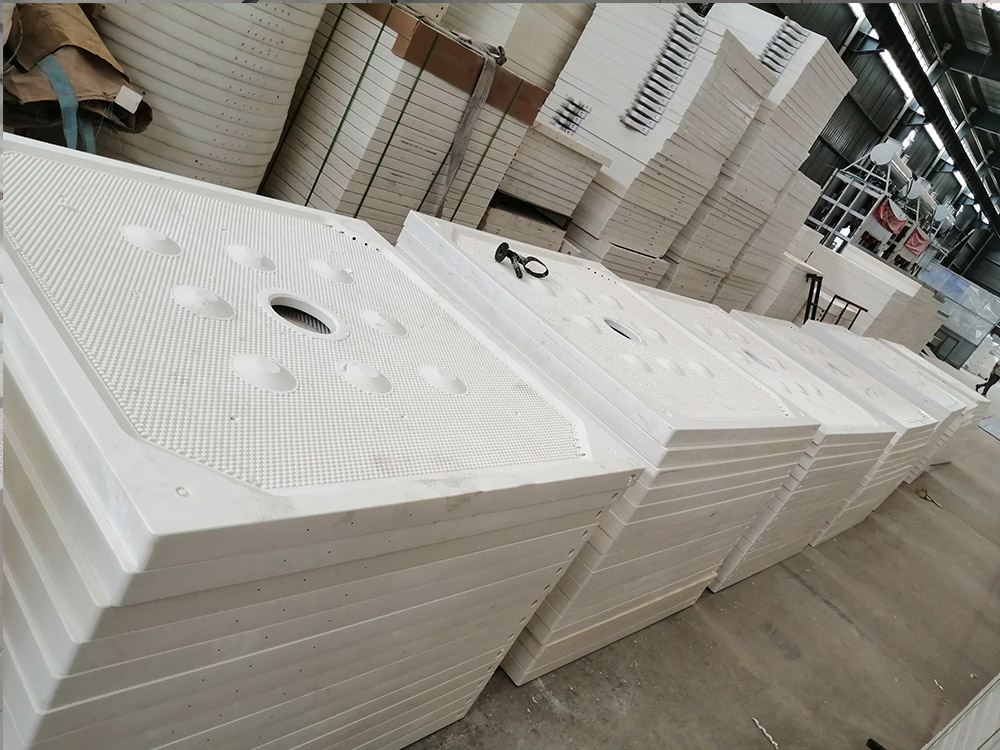

Filter Plate is the key part of filter press. It's used to support filter cloth and store the heavy filter cakes. The quality of the filter plate (especially the flatness and precision of the filter plate) is directly related to the filtering effect and service life.

Different materials, models and qualities will affect the whole machine's filtration performance directly. Its feeding hole, filter points distribution (filter channel) and filtrate discharge channels have different designs according to different materials.

|

Material of filter plates |

PP plate, membrane plate, cast iron filter plate, stainless steel filter plate. |

|

Form of feeding |

Middle feeding, corner feeding, upper middle feeding, etc. |

|

Form of filtrate discharging |

Seen flow, unseen flow. |

|

Type of plate |

Plate-frame filter plate, chamber filter plate, membrane filter plate, recessed filter plate, round filter plate. |

✧ Product Features

Polypropylene (PP), also known as high molecular weight polypropylene. This material has excellent resistance to various acids and alkali, including strong acid hydrofluoric acid. It has strong toughness and rigidity, improving the compression sealing performance. Suitable for filter presses.

1. Modified and reinforced polypropylene with a special formula, molded in one go.

2. Special CNC equipment processing, with a flat surface and good sealing performance.

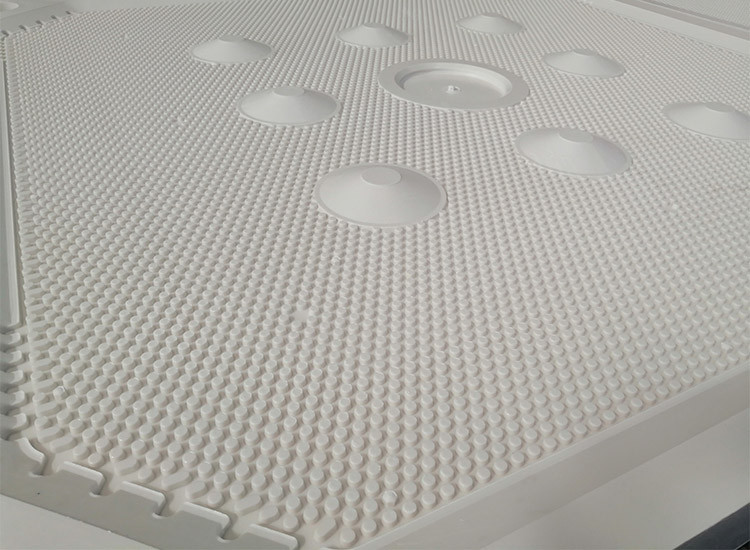

3. The filter plate structure adopts a variable cross-section design, with a conical dot structure distributed in a plum blossom shape in the filtering part, effectively reducing the filtration resistance of the material;

4. The filtration speed is fast, the design of the filtrate flow channel is reasonable, and the filtrate output is smooth, greatly improving the working efficiency and economic benefits of the filter press.

5. The reinforced polypropylene filter plate also has advantages such as high strength, light weight, corrosion resistance, acid, alkali resistance, non-toxic, and odorless.

✧ Application Industries

The filter plate has strong adaptability and excellent product quality, and is widely used in fields such as chemical industry, light industry, petroleum, pharmaceuticals, food, resource development, metallurgy and coal, national defense industry, environmental protection, etc.

✧ Filter Plate Parameter

| Model(mm) | PP Camber | Diaphragm | Closed | Stainless steel | Cast Iron | PP Frame and Plate | Circle |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ | √ | √ | √ | ||

| 630×630 | √ | √ | √ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ | √ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ | √ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Temperature | 0-100℃ | 0-100℃ | 0-100℃ | 0-200℃ | 0-200℃ | 0-80℃ | 0-100℃ |

| Pressure | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |

| Filter Plate Parameter List | |||||||

| Model(mm) | PP Camber | Diaphragm | Closed | Stainless steel | Cast Iron | PP Frame and Plate | Circle |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ |

√ | √ | √ | ||

| 630×630 | √ | √ |

√ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ |

√ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ |

√ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Temperature | 0-100℃ | 0-100℃ | 0-100℃ | 0-200℃ | 0-200℃ | 0-80℃ | 0-100℃ |

| Pressure | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |