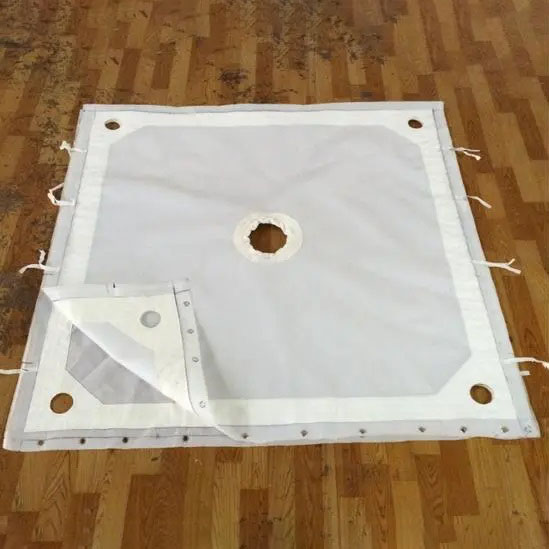

PET Filter Cloth for Filter Press

Material Performance

1 It can withstand acid and neuter cleaner, has wear resistance and corrosion resistance, has good recovery ability, but poor conductivity.

2 Polyester fibers generally have a temperature resistance of 130-150℃.

3 This product not only has the unique advantages of ordinary felt filter fabrics, but also has excellent wear resistance and high cost-effectiveness, making it the most widely used variety of felt filter materials.

4 Heat resistance: 120 ℃;

Breaking elongation (%): 20-50;

Breaking strength (g/d): 438;

Softening point (℃): 238.240;

Melting point (℃): 255-26;

Proportion: 1.38.

Filtration Features of PET short-fiber filter cloth

The raw material structure of polyester short fiber filter cloth is short and woolly, and the woven fabric is dense, with good particle retention, but poor stripping and permeability performance. It has strength and wear resistance, but its water leakage is not as good as polyester long fiber filter cloth.

Filtration Features of PET long-fiber filter cloth

PET long fiber filter cloth has a smooth surface, good wear resistance, and high strength. After twisting, this product has higher strength and better wear resistance, resulting in good permeability, fast water leakage, and convenient cleaning of the fabric.

Application

Suitable for sewage and sludge treatment, chemical industry, ceramics industry, pharmaceutical industry, smelting, mineral processing, coal washing industry, food and beverage industry, and other fields.

✧ Parameter List

PET short-fiber filter cloth

|

Model |

Weaving Mode |

Density Pieces/10cm |

Breaking Elongation Rate% |

Thickness mm |

Breaking Strength |

Weight g/m2 |

Permeability L/M2.S |

|||

|

Longitude |

Latitude |

Longitude |

Latitude |

Longitude |

Latitude |

|||||

|

120-7(5926) |

Twill |

4498 |

4044 |

256.4 |

212 |

1.42 |

4491 |

3933 |

327.6 |

53.9 |

|

120-12(737) |

Twill |

2072 |

1633 |

231.6 |

168 |

0.62 |

5258 |

4221 |

245.9 |

31.6 |

|

120-13(745) |

Plain |

1936 |

730 |

232 |

190 |

0.48 |

5625 |

4870 |

210.7 |

77.2 |

|

120-14(747) |

Plain |

2026 |

1485 |

226 |

159 |

0.53 |

3337 |

2759 |

248.2 |

107.9 |

|

120-15(758) |

Plain |

2594 |

1909 |

194 |

134 |

0.73 |

4426 |

2406 |

330.5 |

55.4 |

|

120-7(758) |

Twill |

2092 |

2654 |

246.4 |

321.6 |

0.89 |

3979 |

3224 |

358.9 |

102.7 |

|

120-16(3927) |

Plain |

4598 |

3154 |

152.0 |

102.0 |

0.90 |

3426 |

2819 |

524.1 |

<20.7 |

PET long-fiber filter cloth

|

Model |

Weaving Mode |

Breaking Elongation Rate% |

Thickness mm |

Breaking Strength |

Weight g/m2 |

Permeability L/M2.S |

||

|

|

Longitude |

Latitude |

Longitude |

Latitude |

||||

|

60-8 |

Plain |

1363 |

|

0.27 |

1363 |

|

125.6 |

130.6 |

|

130# |

|

111.6 |

|

221.6 |

||||

|

60-10 |

2508 |

|

0.42 |

225.6 |

|

219.4 |

36.1 |

|

|

240# |

|

958 |

|

156.0 |

||||

|

60-9 |

2202 |

|

0.47 |

205.6 |

|

257 |

32.4 |

|

|

260# |

|

1776 |

|

160.8 |

||||

|

60-7 |

3026 |

|

0.65 |

191.2 |

|

342.4 |

37.8 |

|

|

621 |

|

2288 |

|

134.0 |

||||