A self-cleaning filter is a precision device that directly intercepts impurities in water using a filter screen. It removes suspended solids and particles from the water, reduces turbidity, purifies the water quality, and minimizes the formation of dirt, algae, and rust in the system. This helps to purify the water and ensure the normal operation of other equipment in the system.

Part 1: Working Principle

Filtration Process: The water to be filtered enters the filter through the water inlet and flows through the filter screen. The pore size of the filter screen determines the filtration accuracy. Impurities are retained inside the filter screen, while the filtered water passes through the filter screen and enters the water outlet, then flows to the water – using equipment or the subsequent treatment system. During

- the filtration process, as impurities continuously accumulate on the surface of the filter screen, a certain pressure difference will form between the inner and outer sides of the filter screen.

- Cleaning Process: When the pressure difference reaches the set value or the set cleaning time interval is reached, the self – cleaning filter will automatically start the cleaning program. The brush or scraper is driven by a motor to rotate and scrub the surface of the filter screen. The impurities attached to the filter screen are brushed off and then flushed towards the sewage outlet by the water flow for discharge. During the cleaning process, there is no need to interrupt the system operation, achieving online cleaning without affecting the normal operation of the filtration system.

Although the specific structures and working methods of self – cleaning filters of different types and brands may vary, the basic principle is to intercept impurities through the filter screen and use an automatic cleaning device to regularly remove the impurities on the filter screen, ensuring the filtration effect and water flow capacity of the filter.

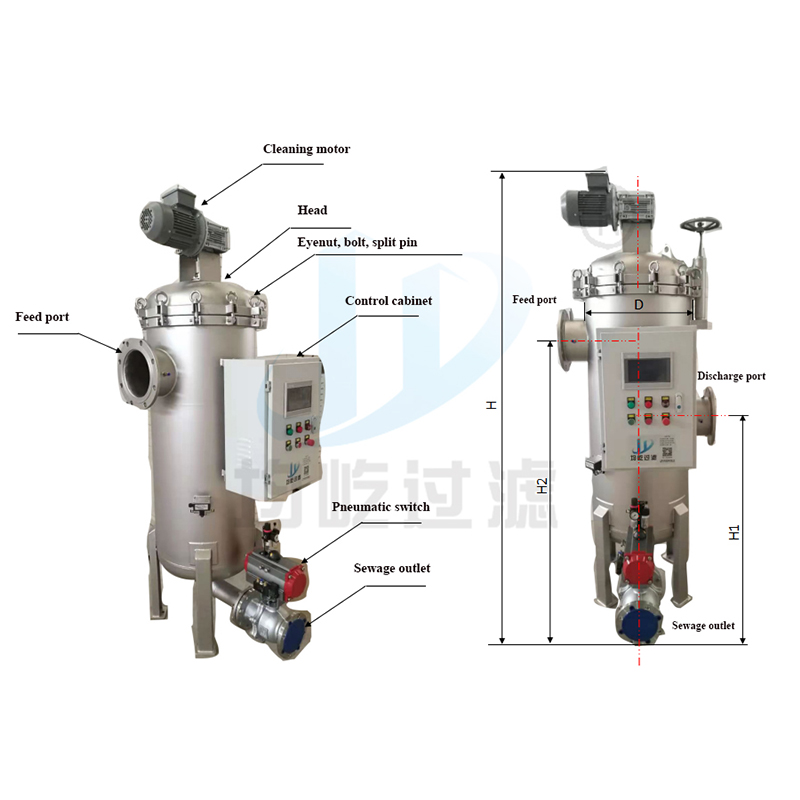

Part 2: Main Components

- Filter Screen: Common materials include stainless steel and nylon. Stainless steel filter screens are characterized by high strength and corrosion resistance, suitable for various water qualities and working environments. Nylon filter screens are relatively soft and have high filtration accuracy, often used for filtering fine particles.

- Housing: Usually made of materials like stainless steel. Stainless steel housing features high strength and corrosion resistance, which can adapt to different water qualities and working conditions.

- Motor and Driving Device: During the automatic cleaning process, the motor and driving device provide power for the cleaning components (such as brushes and scrapers), enabling them to effectively clean the filter screen.

- Pressure Difference Controller: It continuously monitors the pressure difference between the inner and outer sides of the filter screen and controls the start of the cleaning program according to the set pressure difference threshold. When the pressure difference reaches the set value, it indicates that there is a large amount of impurity accumulation on the surface of the filter screen, and cleaning is required. At this time, the pressure difference controller will send a signal to start the cleaning device.

- Sewage Valve: During the cleaning process, the sewage valve is opened to discharge the cleaned impurities from the filter. The opening and closing of the sewage valve are automatically controlled by the control system to ensure the smooth progress of the cleaning process.

- Cleaning Components (Brushes, Scrapers, etc.): The design of the cleaning components needs to consider the compatibility with the filter screen to ensure that the impurities on the filter screen can be effectively removed without damaging the filter screen.

- PLC Control System: It controls and manages the operation of the entire self – cleaning filter, including monitoring the pressure difference, controlling the start and stop of the motor, and the opening and closing of the sewage valve. The control system can automatically complete the filtration and cleaning processes according to the preset program, and can also be manually intervened

- Part 3: Advantages

- High Degree of Automation: The self – cleaning filter can automatically start the cleaning program according to the set pressure difference or time interval, without the need for frequent manual operation. For example, in industrial circulating water systems, it can operate continuously and stably, greatly reducing the labor cost and intensity of manual maintenance

Continuous Filtration: There is no need to interrupt the system operation during the cleaning process, achieving online cleaning. For instance, in the filtration

- section of a sewage treatment plant, it can ensure that sewage passes through the filter without interruption, without affecting the continuity of the entire treatment process and improving production efficiency.

- High Filtration Accuracy: The filter screen has a variety of pore size specifications, which can meet different filtration accuracy requirements. In the preparation of ultrapure water in the electronics industry, it can effectively remove tiny particulate impurities and ensure the high purity of water quality.

- Long Service Life: Due to the automatic cleaning function, the blockage and damage of the filter screen are reduced, extending the service life of the filter screen and the entire filter. Generally, with proper maintenance, the service life of a self – cleaning filter can reach more than 10 years.

- Wide Application Range: It is suitable for fluid filtration in various industries and different types, such as liquid filtration in industries like chemical, power, food and beverage, as well as water filtration in irrigation systems.

Post time: Mar-14-2025