1、Background overview

A medium-sized chemical plant in Mexico faced a common industrial challenge: how to efficiently filter water for the physical chemical industry to ensure water quality in its production process. The plant needs to handle a flow rate of 5m³/h with a solid content of 0.005% in the water. For this need, Shanghai Junyi provides a solution.

2、System design and selection

(1)Filter equipment

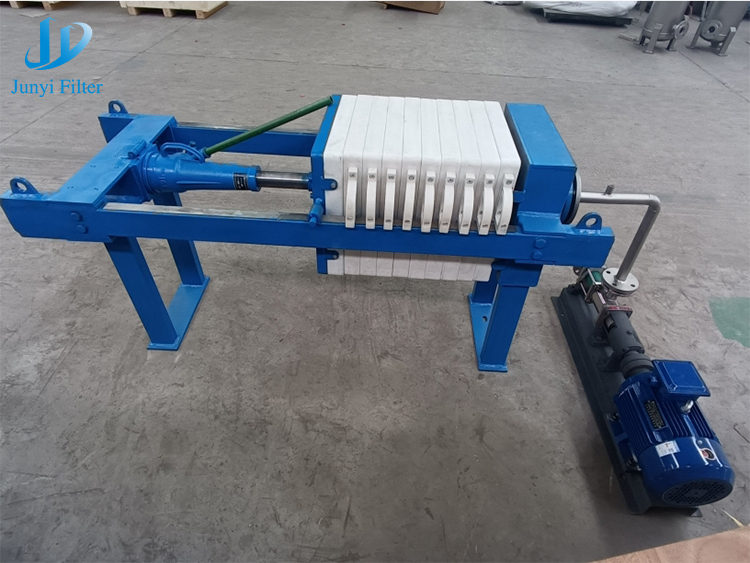

Selection highlights: For the specific needs of the customer, we selected 320 jack filter press, 2 square meters of filtration area,9 high-efficiency filter plates. This design can effectively cope with the water body with low concentration solid content, and achieve fast and thorough solid-liquid separation through physical pressure to ensure that the effluent quality meets the requirements of the subsequent process.

Material selection: Considering the corrosion and chemical stability requirements of chemical water, we use carbon steel as the main structural material, sprayed with epoxy coating, strong corrosion resistance, suitable for harsh environment; High mechanical strength, long service life; Smooth surface, not easy to attach dirt, easy to clean, improve work efficiency.

(2)Conveying equipment

Screw pump

Technical parameters: Equipped with 2.2Kw motor, lift up to 60m, to meet the long-distance, high lift transmission needs. The inlet and outlet are 50mm and 40mm respectively, which is easy to seamlessly connect with the pipeline system.

Material advantage: The liquid contact part is made of 304 stainless steel, which has excellent corrosion resistance to ensure that the water quality is not polluted during the transportation process. The stator is made of fluorine rubber, which further enhances the chemical resistance and sealing property of the pump.

Application effect: Screw pump with its stable flow output and low shear force, to ensure that the chemical water with very low solid content does not produce secondary pollution in the transportation process, to maintain the purity of water quality.

Diaphragm Pump (QBK-40)

Selection reason: As a backup or auxiliary pump, QBK-40 stainless steel diaphragm pump with its strong self-priming capacity, no leakage characteristics, to provide additional security for the system. The material selection is also stainless steel to ensure the durability and corrosion resistance of the pump body.

Application advantages: When short downtime is required for maintenance or to respond to sudden flow changes, the diaphragm pump can respond quickly to ensure continuous and stable operation of the system, while avoiding production disruptions caused by down

Junyi jack filter press

2、Implementation effect

Since its operation, the filtration and conveying system has significantly improved the water quality of our customers’ chemical production lines in Mexico, effectively reducing process failures and product quality fluctuations caused by water quality problems. The equipment has stable performance and good filtering effect to meet the production needs of customers. Customers are satisfied with our products and services, and expressed their willingness to establish a long-term cooperative relationship with our company. In the future, Shanghai Junyi will continue to work hard to provide more overseas customers with professional filtration solutions.

Post time: Jul-26-2024