In the activated carbon decolorization process, the treatment of 3% lactic acid solution faces two major challenges: high temperature (> 80℃) and weakly acidic corrosion. Traditional polypropylene filter plates are difficult to meet the requirements, and stainless steel filter plates need to be used to ensure stability.

Core configuration scheme

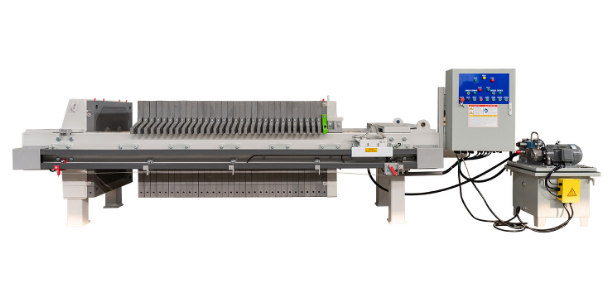

Equipment model: XAYZ100/1000 Chamber Filter Press

Filtration area: 100 square meters (1500L volume)

Temperature-resistant component: Stainless steel filter plate (resistant to 80℃ high temperature)

Acid-resistant design: 750B type filter cloth (200-350 mesh)

Automation: Hydraulic pressing + automatic plate pulling system

Technological advantage

1. High-temperature stability: Stainless steel filter plates ensure reliable operation under high-temperature conditions

2. Dual protection: Simultaneously address the issues of high-temperature deformation and acidic corrosion

3. High-efficiency production: The automatic plate-pulling system increases operational efficiency by 30%

4. Economical and practical: The carbon steel main body balances performance and cost

Application suggestions

Regularly inspect the integrity of the filter cloth of the chamber filter press

Establish a standardized cleaning and maintenance process

This automatic filter press has been successfully applied in multiple lactic acid production projects, effectively solving the problem of activated carbon separation. In the future, by continuously optimizing the filter materials, the process efficiency will be further enhanced.

Post time: Apr-25-2025