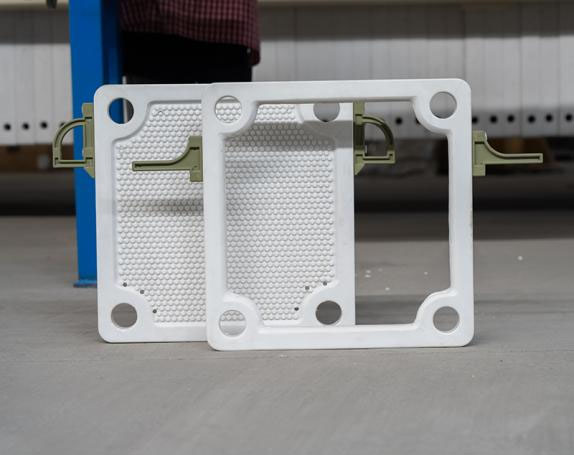

High Temperature Filter Plate

✧ Product Features

1. High temperature resistance, high sealing.

2. Modified and reinforced polypropylene with a special formula, molded in one go.

3. Special CNC equipment processing, with a flat surface and good sealing performance.

4. The filter plate structure adopts a variable cross-section design, with a conical dot structure distributed in a plum blossom shape in the filtering part, effectively reducing the filtration resistance of the material.

5. The filtration speed is fast, the design of the filtrate flow channel is reasonable, and the filtrate output is smooth, greatly improving the working efficiency and economic benefits of the filter press.

| Filter Press Model Guidance | |||||

| Liquid name | Solid-liquid ratio (%) | Specific gravity of solids | Material status | PH value | Solid particle size (mesh) |

| Temperature (℃) | Recovery of liquids/solids | Water content of filter cake | Working hours/day | Capacity/day | Whether the liquid evaporates or not |

✧ Application Industries

Widely used for high-temperature gas filtration in petrochemical industry, filtration of various high-temperature, corrosive liquids, and catalysts; Purification of high-temperature flue gas in the metallurgical industry; Filtration of other high-temperature gases and liquids.

✧ Filter Press Ordering Instructions

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.

| Filter Plate Parameter List | |||||||

| Model(mm) | PP Camber | Diaphragm | Closed | Stainless steel | Cast Iron | PP Frame and Plate | Circle |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ |

√ | √ | √ | ||

| 630×630 | √ | √ |

√ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ |

√ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ |

√ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Temperature | 0-100℃ | 0-100℃ | 0-100℃ | 0-200℃ | 0-200℃ | 0-80℃ | 0-100℃ |

| Pressure | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |

✧ Video