High-precision Self-cleaning Filters Provide High-quality Filtration and Purification Effects

✧ Product Features

1.The control system of the equipment is responsive and accurate. It can flexibly adjust the pressure difference time and time setting value of backwashing according to different water sources and filtration accuracy.

2.In the backwashing process of the filter equipment, each filter screen is backwashing in turn. This ensures safe and efficient cleaning of the filter and does not affect the continued filtration of other filters.

3. Filter equipment using pneumatic blowdown valve, backwashing time is short, backwashing water consumption is less, environmental protection and economy.

4.The structure design of the filter equipment is compact and reasonable, and the floor area is small, and the installation and movement are flexible and convenient.

5.The electric system of the filter equipment adopts integrated control mode, which can realize remote control and is convenient and effective.

6.Filter equipment can easily and thoroughly remove impurities trapped by the filter screen, cleaning without dead corners.

7. The modified equipment can ensure filtration efficiency and long service life.

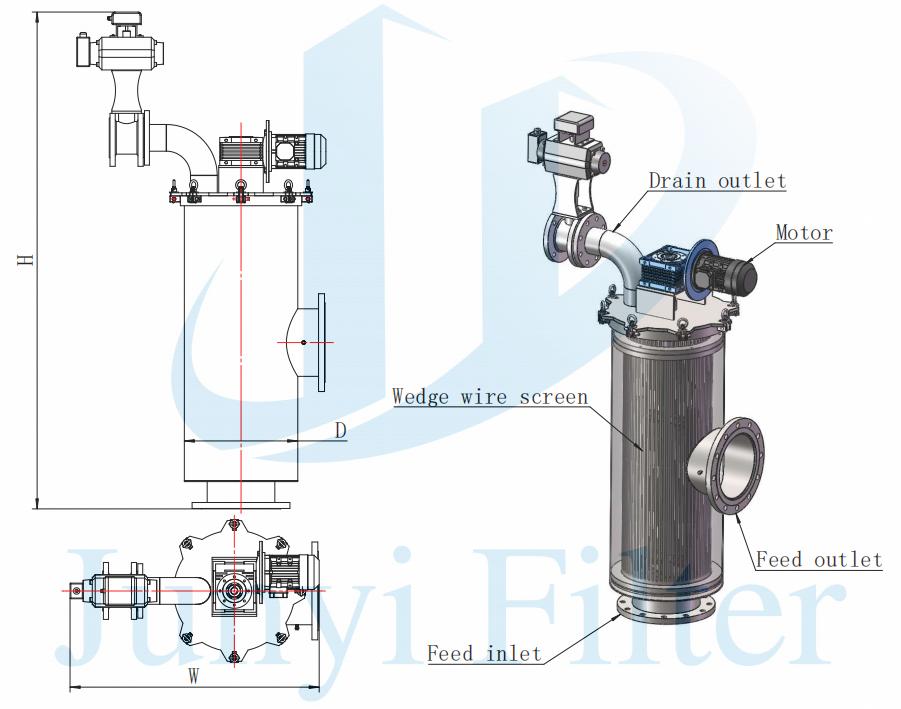

8. The self-cleaning filter first intercepts the impurities on the inner surface of the filter basket, and then the impurity particles adsorbed on the filter screen are brushed under the rotating wire brush or nylon brush and discharged from the blowdown valve with the water flow.

9. Filtration Accuracy: 0.5-200μm; Design Working Pressure: 1.0-1.6MPa; Filtration Temperature: 0-200℃; Cleaning Pressure Differential: 50-100KPa

10. Optional Filter Element: PE/PP Sintered Filter Element, Metal Sintered Wire Mesh Filter Element, Stainless Steel Powder Sintered Filter Element, Titanium Alloy Powder Sintered Filter Element.

11. Inlet and Outlet Connections: Flange, Internal Thread, Outer Thread, quick-load.

✧ Application Industries

Self-cleaning filter is mainly suitable for fine chemical industry, water treatment system, paper making, automotive industry, petrochemical industry, machining, coating and other industries.

✧ Filter Press Ordering Instructions

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.