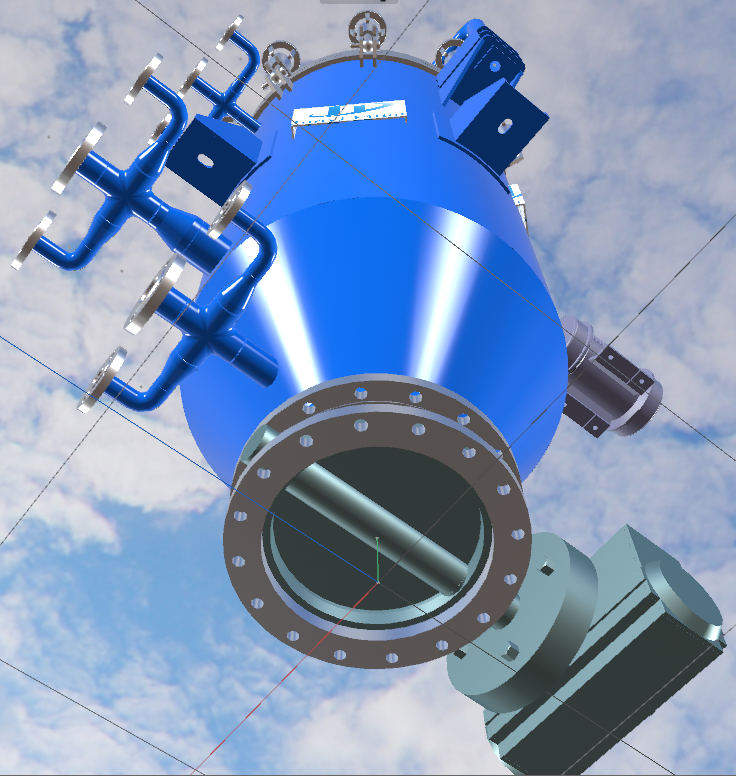

Food Grade Stainless Steel Leaf Filter For Food And Beverage Industry

✧ Product Features

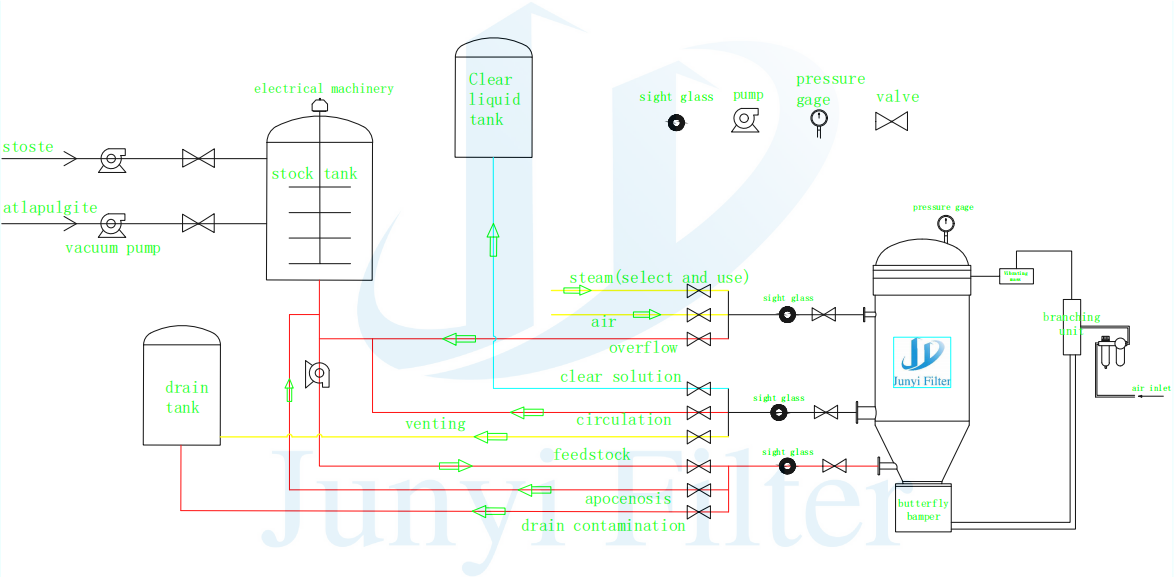

2 The whole process is closed operation, more environmentally friendly and no material loss.

✧ Feeding Process

✧ Application Industries

✧ Filter Press Ordering Instructions

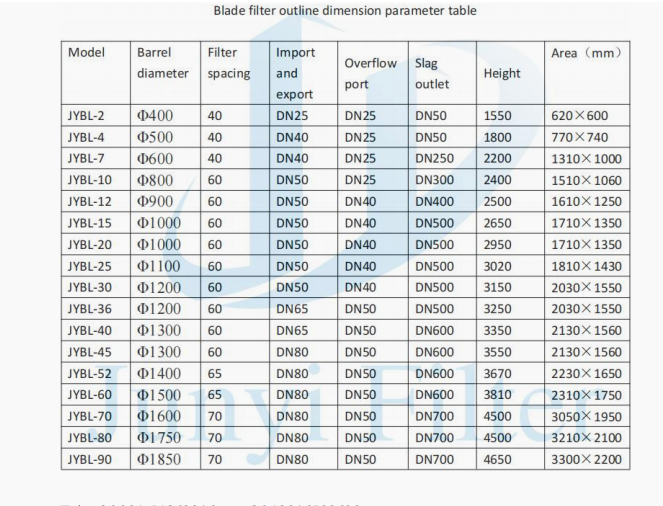

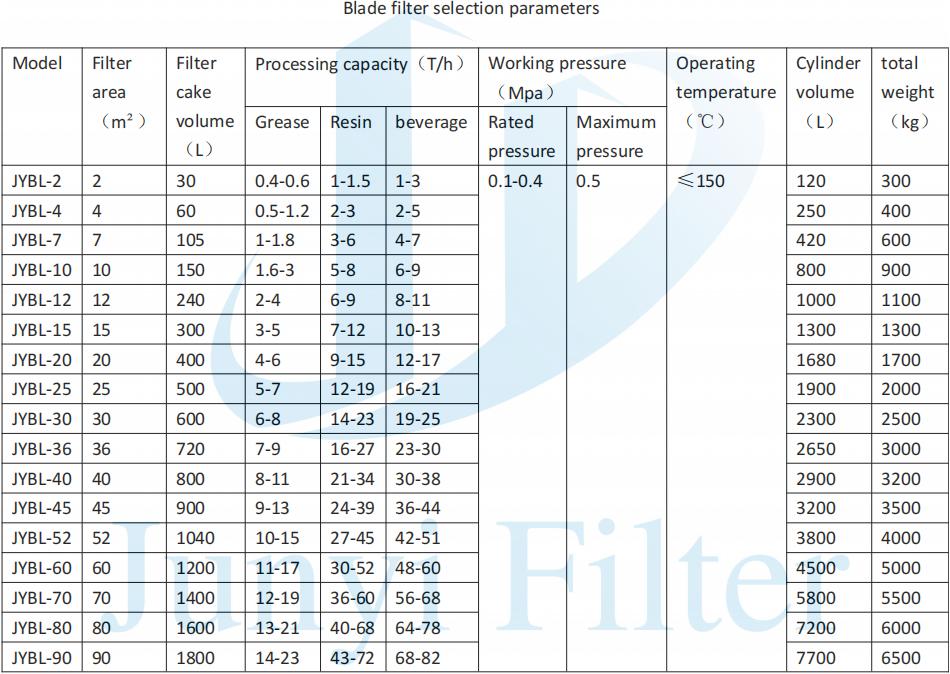

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.