Filter press

-

Automatic belt filter press for sludge dewatering in mineral processing industry

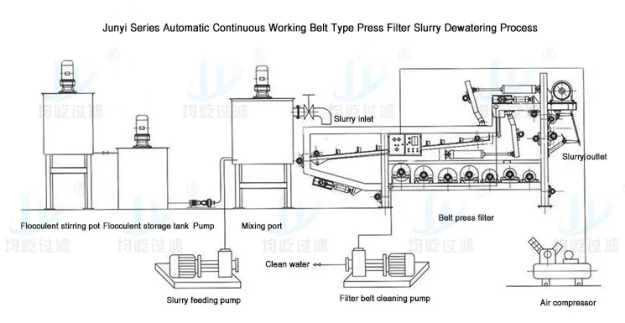

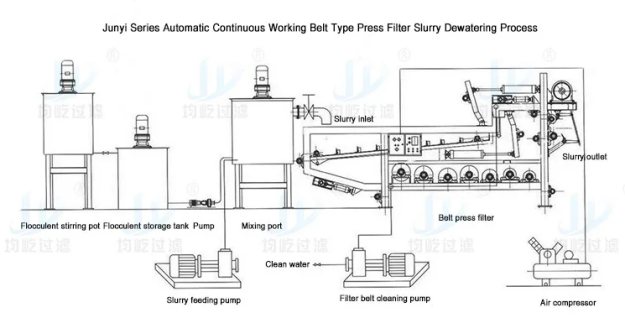

working principle:

Belt filter press is a continuous solid-liquid separation equipment. Its working process is to feed the materials that need to be processed (usually sludge or other suspensions containing solid particles) into the feed inlet of the equipment. The material will first enter the gravity dehydration zone, where a large amount of free water will be separated from the material due to the effect of gravity and flow away through the gaps in the filter belt. Then, the material will enter the wedge-shaped pressing zone, where the space gradually shrinks and an increasing pressure is applied to the material to further squeeze out the moisture. Finally, the material enters the pressing zone, where the remaining water is squeezed out by the pressing rollers to form a filter cake, while the separated water is discharged from below the filter belt.Main structural components:Filter belt: It is the core component of a belt filter press, usually made of materials such as polyester fibers, with certain strength and good filtration performance. The filter belt continuously circulates throughout the entire working process, carrying animal materials through various working areas. The filter belt needs to have good wear resistance and corrosion resistance to ensure long-term stable operation.Drive device: Provides power for the operation of the filter belt, ensuring stable operation at an appropriate speed. It generally includes components such as motors, reducers, and drive rollers. The reducer is driven by the motor, and then the roller is driven by the reducer to rotate, thereby driving the movement of the filter belt.Squeezing roller system: composed of multiple squeezing rollers, which squeeze materials in the squeezing area. The arrangement and pressure settings of these press rollers vary depending on the material and processing requirements. Common combinations of press rollers with different diameters and hardness are used to achieve different pressing effects.Tensioning device: Maintain the tension state of the filter belt to prevent it from loosening during operation. The tensioning device generally achieves the tensioning of the filter belt by adjusting the position or tension of the tensioning roller, ensuring close contact between the filter belt and various working components, thereby ensuring the filtering and pressing effect.Cleaning device: used to clean the filter belt to prevent residual materials on the filter belt from blocking the filter holes and affecting the filtration effect. The cleaning device will rinse the filter belt during operation, and the cleaning solution used is usually water or chemical cleaning agents. The cleaned wastewater will be collected and discharged. -

Mining dewatering system belt filter press

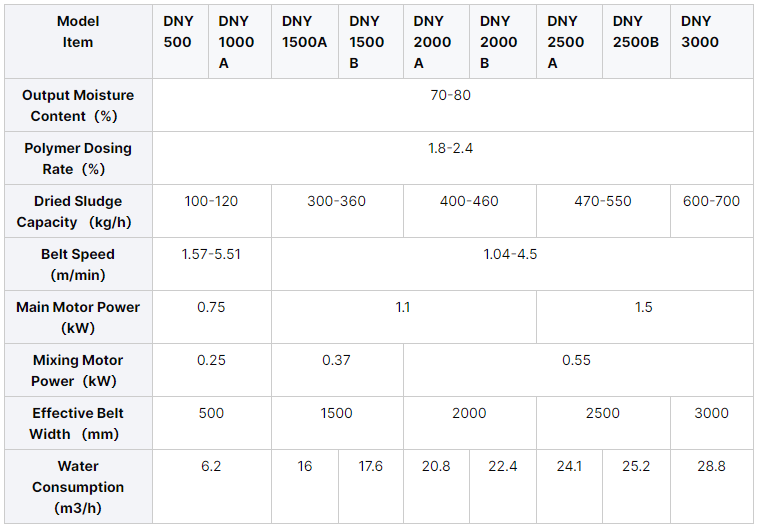

According to the specific sludge capacity requirement, the width of machine can bechosen from 1000mm-3000mm(The choice of thickening belt and filter belt wouldvary/according to different types of sludge). Stainless steel of belt filter press is alsoavailable.

It’s our pleasure to offer the most suitable and most economic effective proposal foryou according to your project! -

Efficient dewatering machine for sludge dewatering

According to the specific sludge capacity requirement, the width of machine can bechosen from 1000mm-3000mm(The choice of thickening belt and filter belt wouldvary/according to different types of sludge). Stainless steel of belt filter press is alsoavailable.

It’s our pleasure to offer the most suitable and most economic effective proposal foryou according to your project! -

Small high-quality sludge belt dewatering machine

>>Sewage treatment equipment suitable for use in a residential area, villages, towns and villages, office buildings, hotels, restaurants, nursing homes, authority, force, highways, railways, factories, mines, scenic spots such as sewage and similar slaughter, aquatic products processing, food and other small and medium size industrial organic wastewater treatment and reuse. >>The sewage treated by the equipment can meet the national discharge standard. The design of sewage treatment mainly is the treatment of sewage and similar industrial organic sewage, its main treatment means is to use at present relatively mature biochemical treatment technology contact oxidation method, water quality design parameter also presses general sewage water quality design calculation.

>>Sewage treatment equipment suitable for use in a residential area, villages, towns and villages, office buildings, hotels, restaurants, nursing homes, authority, force, highways, railways, factories, mines, scenic spots such as sewage and similar slaughter, aquatic products processing, food and other small and medium size industrial organic wastewater treatment and reuse. >>The sewage treated by the equipment can meet the national discharge standard. The design of sewage treatment mainly is the treatment of sewage and similar industrial organic sewage, its main treatment means is to use at present relatively mature biochemical treatment technology contact oxidation method, water quality design parameter also presses general sewage water quality design calculation. -

High quality dewatering machine belt filter press

The belt filter press is designed and manufactured by our factory.

It has S-shaped filter belt, so the pressure of sludge is gradually increased and eased.

It is suitable for the dewatering of organic hydrophilic materials and inorganic hydrophobic materials.

Due to lengthening the settling zone, this series of press filter has rich experience in filter pressing and dewatering of

different types of materials -

-

Automatic pull plate double oil cylinder large filter press

Automatic hydraulic filter press is a batch of pressure filtration equipment, mainly used for solid-liquid separation of various suspensions. It has the advantages of good separation effect and convenient use, and is widely used in petroleum, chemical industry, dyestuff, metallurgy, pharmacy, food, paper making, coal washing and sewage treatment . Automatic hydraulic filter press is mainly composed of the following parts: rack part : includes a thrust plate and a compression plate to support the whole filter mechanism . filter part : composed of filter plate and filter cloth to form a filter unit to realize solid-liquid separation . hydraulic part : hydraulic station and cylinder composition, provide power, to complete the pressing and release action . electrical part : control the operation of the whole filter press, including starting, stopping and the adjustment of various parameters . The working principle of the automatic hydraulic filter press is as follows: When working, the piston in the cylinder body pushes the pressing plate, the filter plate and the filter medium are pressed, so that the material with working pressure is pressurized and filtered in the filter chamber. The filtrate is discharged through the filter cloth, and the cake remains in the filter chamber. After completion, the hydraulic system is automatically released, the filter cake is released from the filter cloth by its own weight, and the unloading is completed . Advantages of fully automatic hydraulic filter press include: efficient filtration : reasonable flow channel design, short filtration cycle, high work efficiency . strong stability : hydraulic system safe and reliable, easy operation and maintenance . widely applicable : suitable for the separation of a variety of suspension, stable and reliable performance . easy operation : high degree of automation, reduce manual operation, improve production efficiency .

-

New function Fully automated belt filter press suitable for mining, sludge treatment

Integrated sewage treatment equipment

The sludge dewatering machine (sludge filter press) is equipped with a vertical thickening and pre-dehydration unit, which enables the dewatering machine to flexibly handle different types of sludge. The thickening section and the filter press section use vertical drive units, and different types of filter belts are used respectively. The overall frame of the equipment is made of stainless steel, and the bearings are made of polymer wear-resistant and corrosion-resistant materials, making the dewatering machine more durable and reliable, and requiring less maintenance. -

Strong corrosion slurry filtration filter press

It is mainly used in the special industry with strong corrosion or food grade, we can produce it fully in stainless steel, including the structure and filter plate or only wrap a layer of stainless steel around the rack.

It can be equipped with feeding pump, cake washing function, dripping tray, belt conveyor, filter cloth washing device, and spare parts according to your requirements.

-

Automatic Filter Press Supplier

It is controlled by PLC, automatic working, widely used in solid-liquid separation process in petroleum, chemical, dyestuff, metallurgy, food, coal washing, inorganic salt, alcohol, chemical, metallurgy, pharmacy, lightindustry, coal, food, textile, environmental protection, energy and other industries.

-

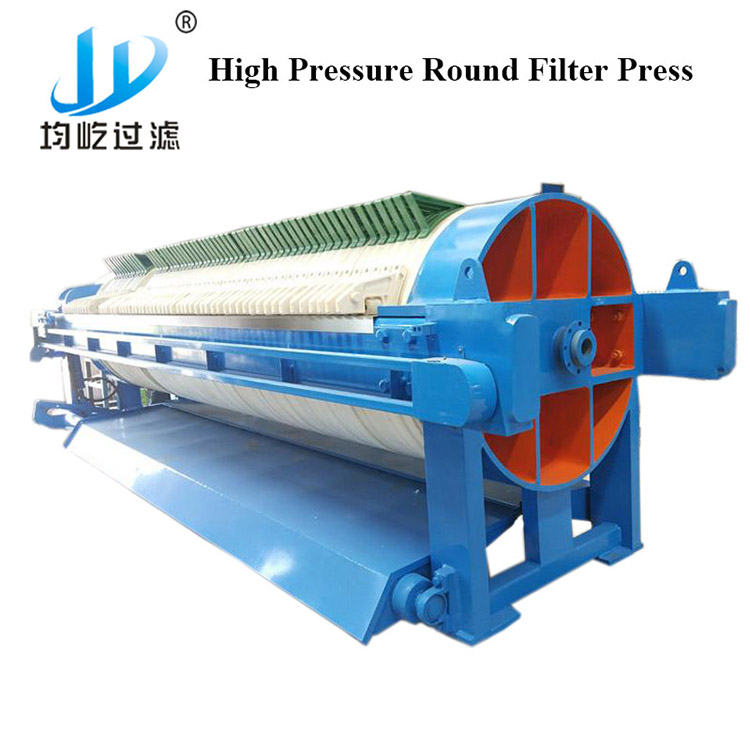

Automatic round Filter Press for Ceramic clay kaolin

Fully automatic round filter press, we can equip with feeding pump, filter plates shifter, drip tray, belt conveyor, etc.

-

Round Filter Press Manual discharge cake

Automatic compress filter plates, manual discharge filter cake, generally for small filter press. Widely used in the ceramic clay, kaolin, yellow wine filtration, rice wine filtration, stone wastewater, and the construction material industry.