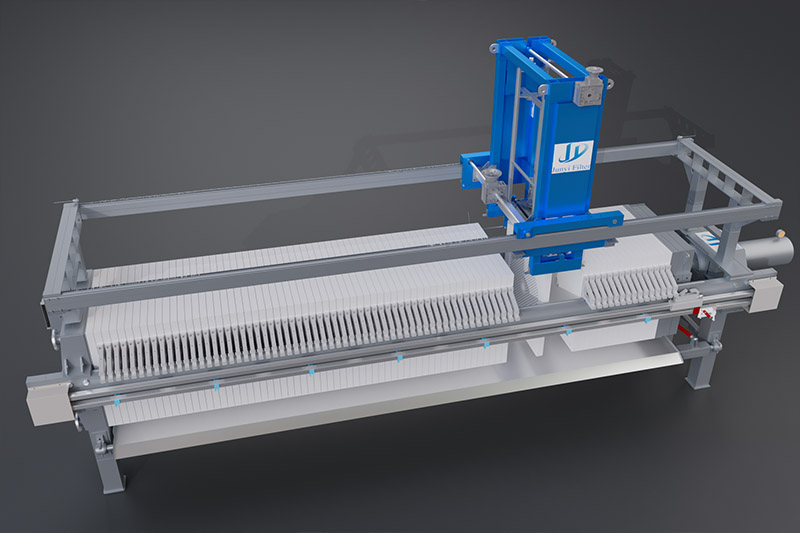

Diaphragm filter press with filter cloth cleaning device

✧ Product Features

Diaphragm filter press matching equipment: Belt conveyor, liquid receiving flap, filter cloth water rinsing system, mud storage hopper, etc.

A-1. Filtration pressure: 0.8Mpa;1.0Mpa;1.3Mpa;1.6Mpa. (Optional)

A-2. Diaphragm squeezing cake pressure: 1.0Mpa;1.3Mpa;1.6Mpa. (Optional)

B、Filtration temperature:45℃/ room temperature; 65-85℃/ high temperature.(Optional)

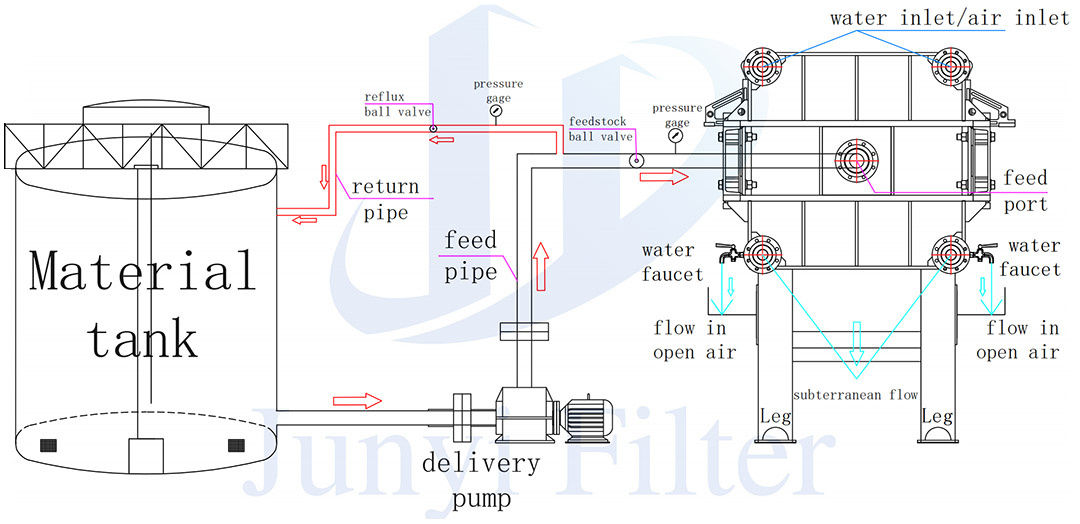

C-1. Discharge method - open flow: Faucets need to be installed below the left and right sides of each filter plate, and a matching sink. Open flow is used for liquids that are not recovered.

C-2. Liquid discharge method -close flow:Under the feed end of the filter press, there are two close flow outlet main pipes, which are connected with the liquid recovery tank. If the liquid needs to be recovered, or if the liquid is volatile, smelly, flammable and explosive, dark flow is used.

D-1. Selection of filter cloth material: The PH of the liquid determines the material of the filter cloth. PH1-5 is acidic polyester filter cloth, PH8-14 is alkaline polypropylene filter cloth. The viscous liquid or solid is preferred to choose twill filter cloth, and the non-viscous liquid or solid is selected plain filter cloth.

D-2. Selection of filter cloth mesh: The fluid is separated, and the corresponding mesh number is selected for different solid particle sizes. Filter cloth mesh range 100-1000 mesh. Micron to mesh conversion (1UM = 15,000 mesh---in theory).

E.Rack surface treatment: PH value neutral or weak acid base; The surface of the filter press frame is sandblasted first, and then sprayed with primer and anti-corrosion paint. The PH value is strong acid or strong alkaline, the surface of the filter press frame is sandblasted, sprayed with primer, and the surface is wrapped with stainless steel or PP plate.

F.Diaphragm filter press operation: Automatic Hydraulic Pressing; Filter cake washing, Automatic Filter Plate Pulling; Filter Plate Vibrating Cake Discharge; Automatic Filter Cloth Rinsing System. Please kindly tell me the functions you need before ordering.

G.Filter cake washing: When solids need to be recovered, the filter cake is strongly acidic or alkaline; When the filter cake needs to be washed with water, please send an email to inquire about the washing method.

H.Filter press feeding pump selection: The solid-liquid ratio, acidity, temperature and characteristics of the liquid are different, so different feed pumps are required. Please send email to inquire.

I.Automatic belt conveyor: The belt conveyor is installed under the plate of filter press, which is used for transporting the discharged cake after the filter plates have been pulled open. This device is suitable for the project which is not convenient to make the base floor. It can delivery the cake to the designated place, which will reduce much labor work.

J.Automatic dripping tray: The drip tray is installed under the plate of filter press. During the filtration process, the two plate trays are in a closed state, which can lead the dripping liquid during the filtration and the cloth washing water to the water collector sideways. After the filtration, the two plate trays will be opened to discharge the cake.

K.The filter press cloth water flushing system: It is installed above the main beam of the filter press, and it is equipped with automatic travelling function, and the filter cloth is automatically rinsed with high pressure water (36.0Mpa) by switching the valve. There are two kinds of structures for rinsing: single-side rinsing and double-side rinsing, in which the double-side rinsing has brushes for good cleaning effect. With the flap mechanism, the rinsing water can be recycled and reused after treatment to save resources; combined with diaphragm press system, it can get lower water content; assembled frame, compact structure, easy to disassemble and transport.

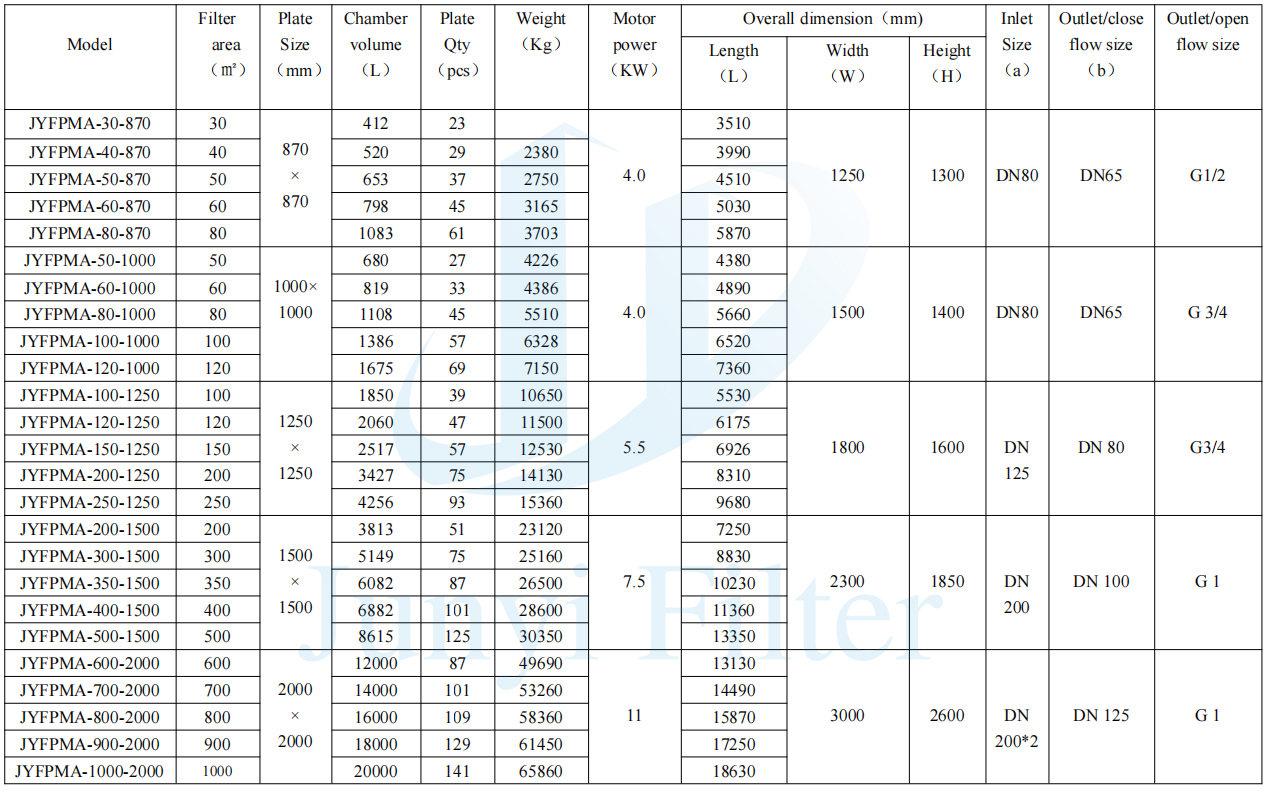

| Filter Press Model Guidance | |||||

| Liquid name | Solid-liquid ratio (%) | Specific gravity of solids | Material status | PH value | Solid particle size (mesh) |

| Temperature (℃) | Recovery of liquids/solids | Water content of filter cake | Working hours/day | Capacity/day | Whether the liquid evaporates or not |

✧ Feeding Process

✧ Application Industries

It is widely used in solid-liquid separation process in petroleum, chemical, dyestuff, metallurgy, pharmacy, food, coal washing, inorganic salt, alcohol, chemical, metallurgy, pharmacy, light industry, coal, food, textile, environmental protection, energy and other industries.

✧ Filter Press Ordering Instructions

1. Refer to the filter press selection guide, filter press overview, specifications and models, select the model and supporting equipment according to the needs.

For example: Whether the filter cake is washed or not, whether the effluent is open or close, whether the rack is corrosion-resistant or not, the mode of operation, etc., must be specified in the contract.

2. According to the special needs of customers, our company can design and produce non-standard models or customized products.

3. The product pictures provided in this document are for reference only. In case of changes, we will not give any notice and the actual order will prevail.

✧ Drawing Of Automatic Filter Press with Cloth Water Flushing System

✧ Automatic Diaphragm Filter Press

✧ Video