Crude Oil Filtratiton Horizaontal Pressure Leaf Filter

✧ Product Features

1. No filter cloth or filter paper is required for filtration, reducing the cost of filtration.

2. The whole process is closed operation, more environmentally friendly and no material loss.

3. The equipment adopts the method of vibration slag removal, which reduces the labor intensity of workers and can realize continuous operation.

4. Pneumatic valve slagging, reducing the labor intensity of workers.

5. The material press or activated carbon in the liquid is filtered by direct filtration or dewatering.

6. Blade filters can completely replace plate and frame filters and are the equipment of choice.

7. Unique design structure, small size; high filtration efficiency; good transparency and fineness of filtrate; no material loss.

8. The equipment is easy to operate, maintain and clean.

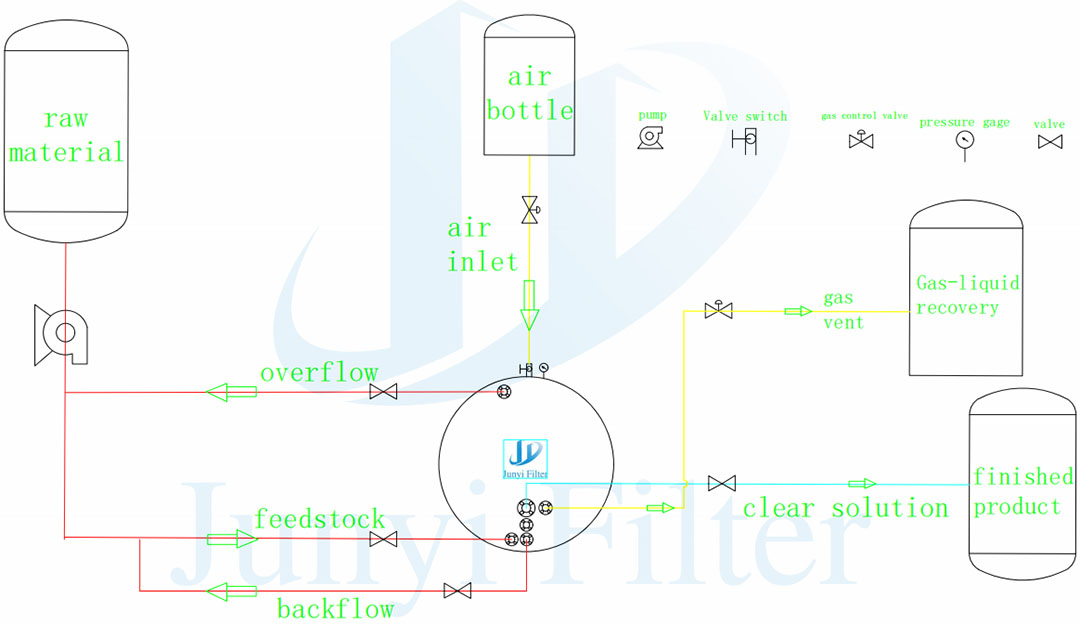

✧ Feeding Process

✧ Blade Filter Application Industries

1. Petroleum and chemical industry: diesel, lubricants, white oil, transformer oil, polyether.

2. Base oils and mineral oils: Dioctyl ester, Dibutyl ester.

3. Fats and oils: crude oil, gasified oil, winterised oil, bleached each.

4. Foodstuffs: gelatine, salad oil, starch, sugar juice, monosodium glutamate, milk, etc.

5. Pharmaceuticals: hydrogen peroxide, vitamin C, glycerol, etc.

6. Paint: varnish, resin paint, real paint, 685 varnish, etc.

7. Inorganic chemicals: bromine, potassium cyanide, fluorite, etc.

8. Beverages: beer, juice, liquor, milk, etc.

9. Minerals: coal chips, cinders, etc.

10. Others: air and water purification, etc.

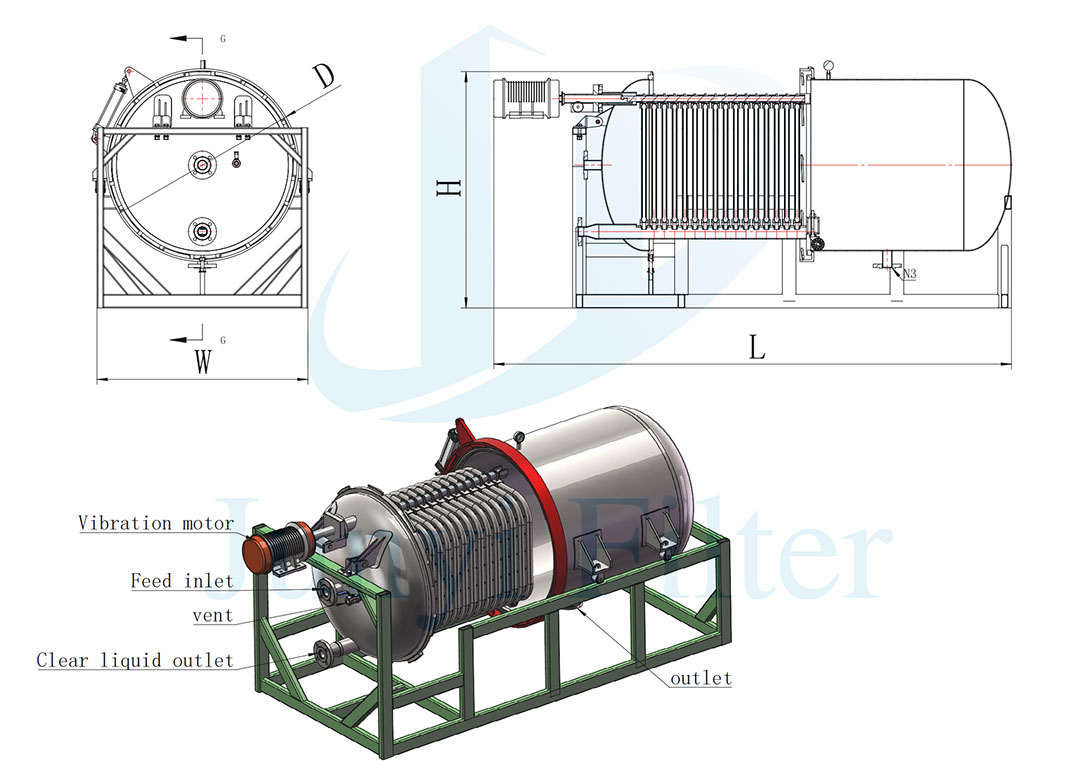

✧ Blade Filter Outline Dimension Parameter Table

| Model | Barrel diameter |

Filter spacing | Import and export |

Overflow port |

Length (mm) |

Width (mm) |

Height (mm) |

| JYBL-2 | Φ400 | 40 | DN25 | DN25 | 1550 | 700 | 800 |

| JYBL-4 | Φ500 | 40 | DN40 | DN25 | 1800 | 800 | 900 |

| JYBL-7 | Φ600 | 40 | DN40 | DN25 | 2200 | 900 | 1000 |

| JYBL-10 | Φ800 | 60 | DN50 | DN25 | 2400 | 1100 | 1200 |

| JYBL-12 | Φ900 | 60 | DN50 | DN40 | 2500 | 1200 | 1300 |

| JYBL-15 | Φ1000 | 60 | DN50 | DN40 | 2650 | 1300 | 1400 |

| JYBL-20 | Φ1000 | 60 | DN50 | DN40 | 2950 | 1300 | 1400 |

| JYBL-25 | Φ1100 | 60 | DN50 | DN40 | 3020 | 1400 | 1500 |

| JYBL-30 | Φ1200 | 60 | DN50 | DN40 | 3150 | 1500 | 1600 |

| JYBL-36 | Φ1200 | 60 | DN65 | DN50 | 3250 | 1500 | 1600 |

| JYBL-40 | Φ1300 | 60 | DN65 | DN50 | 3350 | 1600 | 1700 |

| JYBL-45 | Φ1300 | 60 | DN80 | DN50 | 3550 | 1600 | 1700 |

| JYBL-52 | Φ1400 | 65 | DN80 | DN50 | 3670 | 1700 | 1800 |

| JYBL-60 | Φ1500 | 65 | DN80 | DN50 | 3810 | 1800 | 1900 |

| JYBL-70 | Φ1600 | 70 | DN80 | DN50 | 4500 | 1900 | 2000 |

| JYBL-80 | Φ1750 | 70 | DN80 | DN50 | 4500 | 2050 | 2150 |

| JYBL-90 | Φ1850 | 70 | DN80 | DN50 | 4650 | 2150 | 2250 |

✧ Video