Automatic Candle Filter

✧ Product Features

1、A completely sealed, high safety system with no rotating mechanical moving parts (except for pumps and valves);

2、Fully automatic filtration;

3、Simple and modular filter elements;

4、The mobile and flexible design meets the requirements of short production cycles and frequent batch production;

5、Aseptic filter cake can be realized in the form of dry residue, slurry and re-pulping to be discharged into an aseptic container;

6、Spray washing system for greater savings in the consumption of washing liquid.

7、Nearly 100 per cent recovery of solids and liquids, ensuring batch filtration integrity.

8、Candle filters can be easily cleaned in-line and all parts can be disassembled for inspection;

9、Simple filter cake washing, drying and unloading;

10、In-line sterilisation by steam or chemical methods in steps;

11、The filter cloth is perfectly matched to the nature of the product;

12、It can be used in the production of free granule injections;

13、All sanitary fittings are sealed with O-rings to comply with pharmaceutical production quality flange requirements;

14、The activated carbon filter is equipped with a sterile pump and instrumentation.

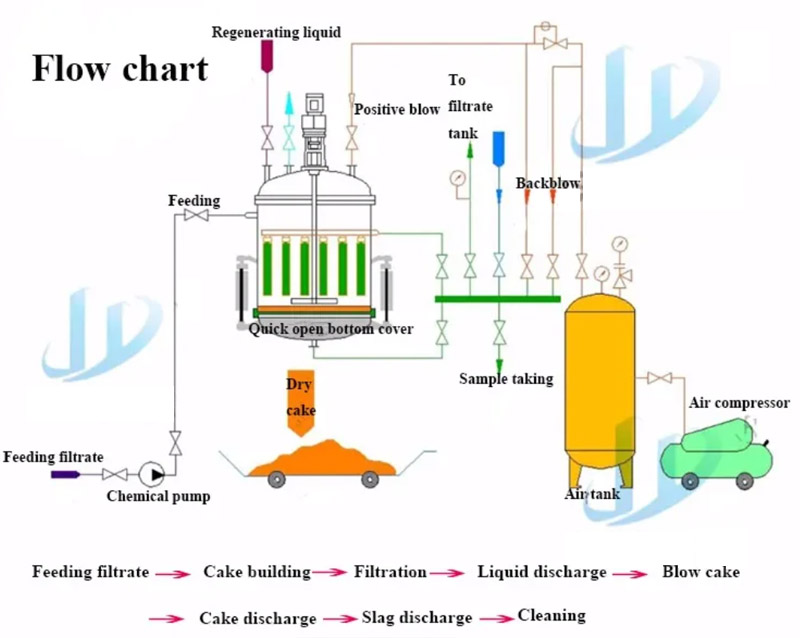

✧ Feeding Process

✧ Application Industries

Applicable industries: petrochemicals, beverages, fine chemicals, oils and fats, water treatment, titanium dioxide, electric power, polysilicon and so on.

Applicable fluids: resin, recycled wax, cutting oil, fuel oil, lubricating oil, machine cooling oil, transformer oil, bone glue, gelatin, citric acid, syrup, beer, epoxy resin, polyglycol, etc.