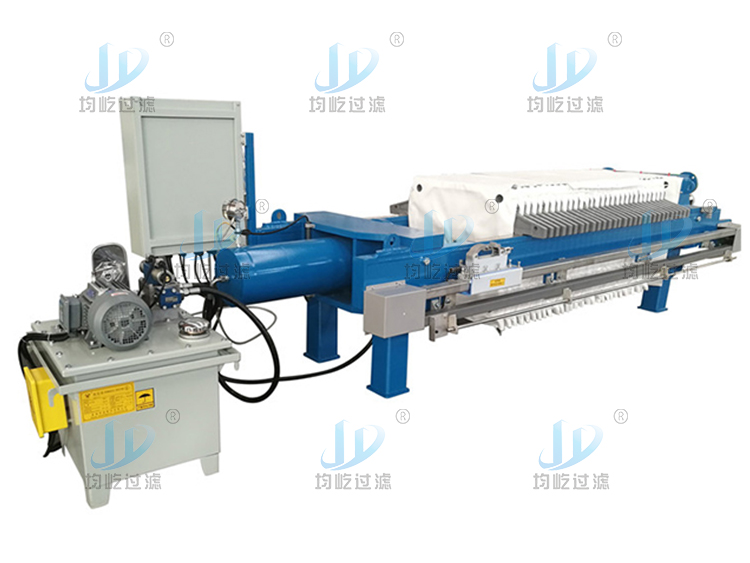

Automatic chamber stainless steel carbon steel filter press with diaphragm pump

Product Overview:

The chamber filter press is an intermittent solid-liquid separation equipment that operates on the principles of high-pressure extrusion and filter cloth filtration. It is suitable for the dehydration treatment of high-viscosity and fine particle materials and is widely used in industries such as chemical engineering, metallurgy, food, and environmental protection.

Core features:

High-pressure dewatering – Utilizing a hydraulic or mechanical pressing system to provide strong squeezing force, significantly reducing the moisture content of the filter cake.

Flexible adaptation – The number of filter plates and the filtration area can be adjusted to meet different production capacity demands, and special material customization is supported (such as corrosion-resistant/high-temperature design).

Stable and durable – High-quality steel frame and reinforced polypropylene filter plates, resistant to pressure and deformation, easy to replace filter cloth, and low maintenance cost.

Applicable fields:

Solid-liquid separation and drying in fields such as fine chemicals, mineral refining, ceramic slurry, and sewage treatment.

Product Features

A、Filtration pressure<0.5Mpa

B、Filtration temperature:45℃/ room temperature; 80℃/ high temperature; 100℃/ High temperature. The raw material ratio of different temperature production filter plates is not the same, and the thickness of filter plates is not the same.

C-1、Discharge method – open flow: Faucets need to be installed below the left and right sides of each filter plate, and a matching sink. Open flow is used for liquids that are not recovered.

C-2、Liquid discharge method close flow:Under the feed end of the filter press, there are two close flow outlet main pipes, which are connected with the liquid recovery tank. If the liquid needs to be recovered, or if the liquid is volatile, smelly, flammable and explosive, dark flow is used.

D-1、Selection of filter cloth material: The pH of the liquid determines the material of the filter cloth. PH1-5 is acidic polyester filter cloth, PH8-14 is alkaline polypropylene filter cloth. The viscous liquid or solid is preferred to choose twill filter cloth, and the non-viscous liquid or solid is selected plain filter cloth.

D-2、Selection of filter cloth mesh: The fluid is separated, and the corresponding mesh number is selected for different solid particle sizes. Filter cloth mesh range 100-1000 mesh. Micron to mesh conversion (1UM = 15,000 mesh—in theory).

E、Rack surface treatment: PH value neutral or weak acid base; The surface of the filter press frame is sandblasted first, and then sprayed with primer and anti-corrosion paint. The PH value is strong acid or strong alkaline, the surface of the filter press frame is sandblasted, sprayed with primer, and the surface is wrapped with stainless steel or PP plate.

F、Filter cake washing: When solids need to be recovered, the filter cake is strongly acidic or alkaline; When the filter cake needs to be washed with water, please send an email to inquire about the washing method.

G、Filter press feeding pump selection: The solid-liquid ratio, acidity, temperature and characteristics of the liquid are different, so different feed pumps are required. Please send email to inquire.