4 Inch DN80 Stainless Steel Pipeline Basket Strainer Filter

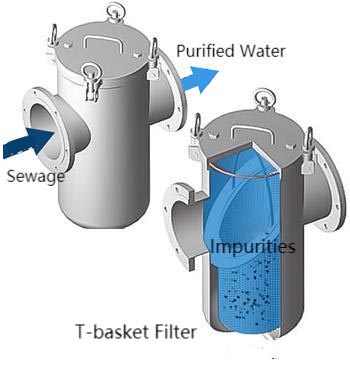

✧ Workflow

The fluid enters from one end into a filter bucket with a certain size of specification, after which the dirt is collected by the filter into the strainers, while the clean filtrate is discharged from the filter outlet. When it is time to clean, simply unscrew the screw plug at the bottom of the main tube, drain the fluid, remove the flange cover, clean and reassemble.

✧ Main filtering role

Removes large particles (coarse filtration), purifies fluids and protects critical equipment (mounted in front of the pump to reduce damage to the pump).

✧ Features

1. Configure the filtration degree of the filter screen according to customer needs.

2. The structure is simple, easy to install, operate, disassemble and maintain.

3. Less wearing parts, low operation and maintenance costs.

4. The stable production process can protect instruments and mechanical equipment and maintain the safety and stability of the whole process.

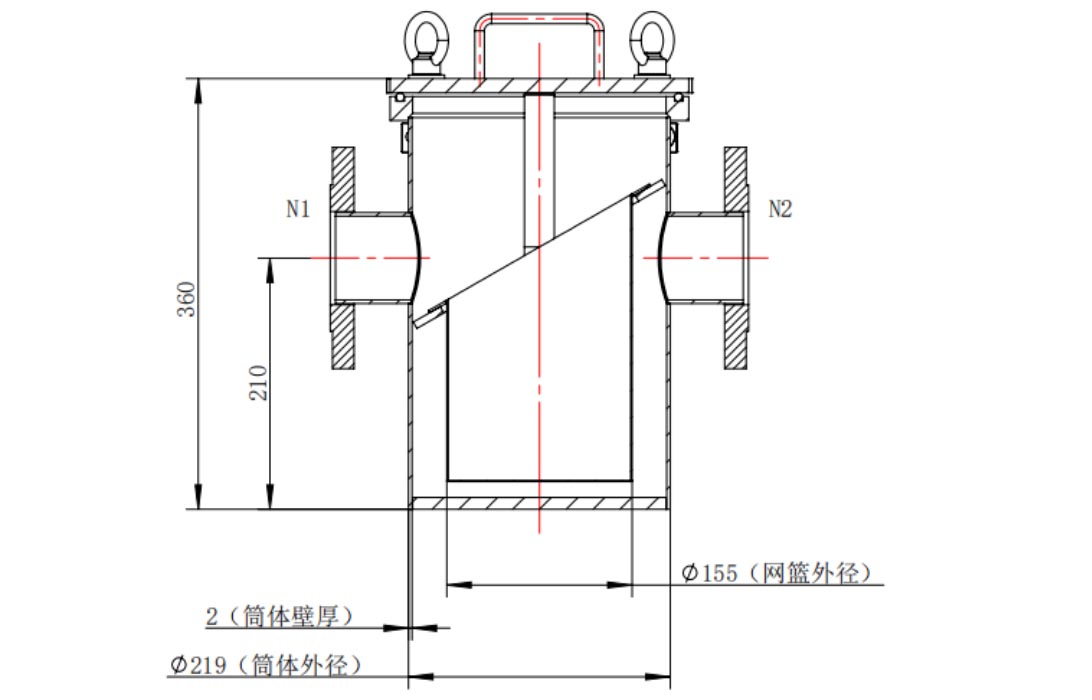

5. The core part of is the filter basket, which is generally welded with a stainless steel punching mesh and a layer stainless steel wire mesh.

6. The housing can be made of carbon steel, SS304, SS316L, or duplex stainless steel.

7. Filter basket is made of stainless steel.

8. Remove large particles, manual regular cleaning the filter basket and used again and again.

9. The suitable viscosity of the equipment is (cp)1-30000; The suitable working temperature is -20--+250℃; Design pressure is 1.0/1.6/2.5Mpa.

✧ Applications

Petroleum, chemical, pharmaceutical, food, environmental protection, etc.

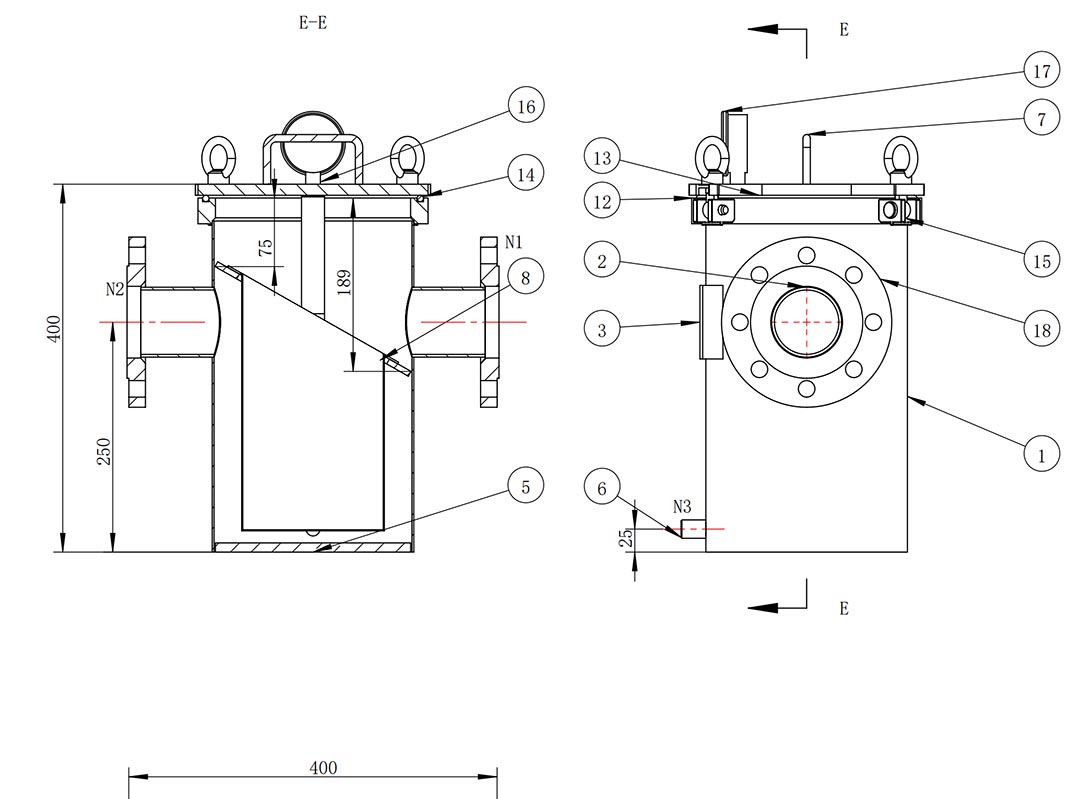

| Model | In/Out Calibre | L(mm) | H(mm) | H1(mm) | D0(mm) | Sewage Outlet |

| JSY-LSP25 | 25 | 220 | 260 | 160 | Φ130 | 1/2″ |

| JSY-LSP32 | 32 | 230 | 270 | 160 | Φ130 | 1/2″ |

| JSY-LSP40 | 40 | 280 | 300 | 170 | Φ150 | 1/2″ |

| JSY-LSP50 | 50 | 280 | 300 | 170 | Φ150 | 3/4″ |

| JSY-LSP65 | 65 | 300 | 360 | 210 | Φ150 | 3/4″ |

| JSY-LSP80 | 80 | 350 | 400 | 250 | Φ200 | 3/4″ |

| JSY-LSP100 | 100 | 400 | 470 | 300 | Φ200 | 3/4″ |

| JSY-LSP125 | 125 | 480 | 550 | 360 | Φ250 | 1″ |

| JSY-LSP150 | 150 | 500 | 630 | 420 | Φ250 | 1″ |

| JSY-LSP200 | 200 | 560 | 780 | 530 | Φ300 | 1″ |

| JSY-LSP250 | 250 | 660 | 930 | 640 | Φ400 | 1″ |

| JSY-LSP300 | 300 | 750 | 1200 | 840 | Φ450 | 1″ |

| JSY-LSP400 | 400 | 800 | 1500 | 950 | Φ500 | 1″ |

| Larger sizes are available on request. | ||||||

1. Compare labels and identify products.

2. Connect the import and export according to the sign.

3. Check that the filter basket is placed correctly.

4. Place the seal ring, press the cover tightly, and tighten the ring uniformly.

5. Install pressure gauge and exhaust valve.

6. Check the seal of the pipe and lid before using the filter, and then inject air to test the pressure.